Many of you remember last March when I was in Denver and made a trip to the Metal Surgeon. As you may recall, the metal surgeon is Jon Bingham from Englewood, Colo. Of course, Jon is originally from England. That’s where he received his degree in fabrication and did internships at Jaguar, Land Rover and Bentley. Those are some pretty impressive places to hone your life skills of coachwork.

Since I found myself in Denver again, I could not resist the temptation of stopping by the Surgeon to see what he was working on. I was excited when Jon’s wife, Valerie, indicated that the doctor was in and could see me.

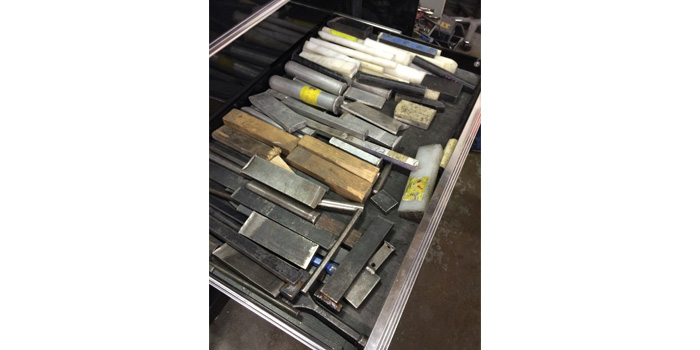

I have to say right up front that this is not your typical production shop. Space is at a premium, and there are even projects hanging from the ceiling. Yes, I said the ceiling – more on that later. Projects here can take over a year. Owners change their minds, and directions change along the way.

The first thing I noticed from last year was a very distinctive object – a 1962 Jeep fleet van. A very rare item, one I don’t ever recall seeing before. I asked Jon why it was still hanging around, and he indicated that the owner had made some changes to the plan and it was now being updated with current V6 power and much fabrication had been done to accommodate this. The cowl work for the larger engine was incredible.

Speaking of hanging around, hanging from the ceiling was what looked like a torpedo! Actually, it was an extended range fuel tank from a WWII bomber. Of course I had to ask, why? Well, a client is having Jon fabricate it into a Bonneville Salt Flats racer. Expected speed? Approximately 146 miles per hour. Interesting, but I never would have guessed that one.

There was also a 1967 VW microbus, not the one from last year but a new one from the same owner. You’ll notice in the picture that there is filler in the side of it. When Jon and his crew are done, the panel will be laser straight with no filler. That’s part of the allure of this kind of work. I also noticed a 914 Porsche sitting there that was having fender extensions added. Jon took the time to show me how they weld them on, file the welds and then work the metal so the joint is not visible. It is truly an art form.

Of course, there were others we looked at. A father-and-son ’67 Mustang that was getting quarters and rockers and a very cool 1952 Chevy cab-over truck cab. The more odd the item is, the more likely it is to end up here. New panels can be fabricated to almost perfect reproduction by the surgeons.

I also spotted a very interesting item in the back of the shop. When I asked about it, the answer was, “Top secret!” I was not allowed to write about it or take any pictures. I will tell you that it is so rare that the owners would only give the Surgeon portions of the car at a time. The rear part of the body and driver’s compartment were there when I was there, and the fabrication of panels for this very low production vehicle was flawless.

I was sad to have my appointment with the doctor come to an end. His passion and dedication to the trade is inspiring. I thank both Jon and Valerie for giving me their time and wish them continued success.

This is a great business we work in, and I’m glad there are so many facets of it available to us. Go find your niche!