The decision to repair, replace or section a structural component depends mainly on current industry recommendations. With all of the new vehicles being developed and introduced yearly, manufacturers may publish many structural repair and sectioning procedures that we don’t know exist.

The decision to repair, replace or section a structural component depends mainly on current industry recommendations. With all of the new vehicles being developed and introduced yearly, manufacturers may publish many structural repair and sectioning procedures that we don’t know exist.

This article provides Audi’s repair recommendations and service procedures for the 2000-2007 TT.

Service Information

Always refer to ALLDATA Collision for safety procedures, identification of material types, recommended refinish materials, removal and installation

procedures.

Always refer to AUDI for questions relating to applicable or non-applicable warranty repair

information.

CAUTION: Read and follow all of the instructions from the manufacturers line of painting materials, equipment, and protective gear.

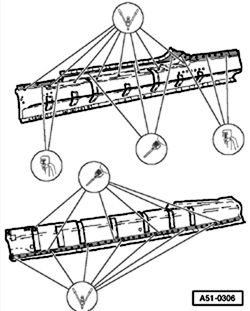

Replacement Part(s)

• Sidemember

• Pop rivet nuts

NOTE:

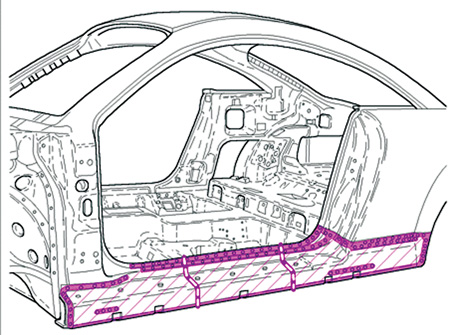

• Before replacing, check whether inner sidemember can be straightened.

• Deformation of up to 10 mm per 100 mm length is permissible.

• Tears up to 100 mm in length may be welded.

• Partial replacement is possible with the separa-

ting cuts shown. Step separating area SG continuous seam.

• Install pop rivet nuts using riveting pliers VAG 1765.

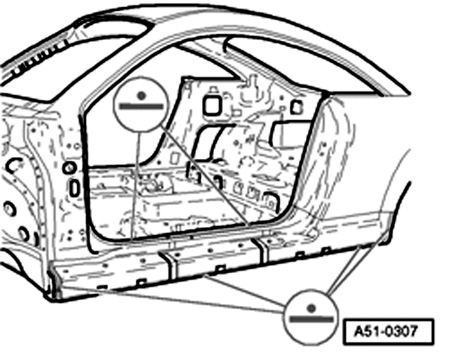

Separating Locations

1. Separate original joint.

2. Make separating cuts on sidemember according to degree of damage.

3. Remove remaining material.

Preparing New Part

1. Make holes in outer joint surface of new part.

2. Drill sidemember for plug-welding.

3. Install pop rivet nuts using riveting pliers VAG 1765.

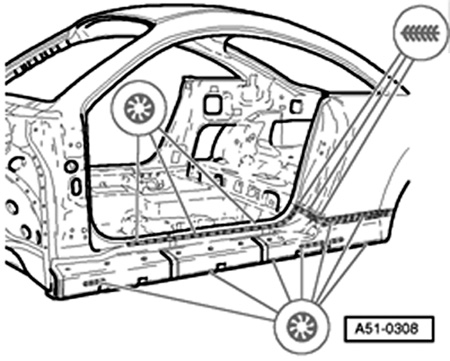

Welding In

1. Weld in sidemember, RP spot weld seam.

2. Weld in sidemember, SG plug weld seam.

3. Make 4 x 20 mm SG continuous seam instead of bonded joint.

© 2008 ALLDATA LLC. All rights reserved. All technical information, images and specifications are from the ALLDATA Product. ALLDATA is a registered trademark and ALLDATA Collision is a mark of ALLDATA LLC. All other marks are the property of their respective holders. Audi and TT are registered trademarks of Audi of America Corporation and are being used solely for reference and application purposes.

Written by Dan Espersen, ALLDATA Collision Program Manager. He’s a Gold Pin Member of the Collision Industry Conference (CIC) and holds an AA Degree in Automotive Technology. He has 17 years of experience in the collision industry and 17 years of experience in the automotive industry.