Car-O-Liner

Car-O-Liner

What you should be shopping for is a bench – a machine-milled, datum controlling bench with universal fixturing to hold while pulling and hold new parts in place for welding, bonding and riveting. The bench must be capable of multiple-point anchoring as designated by BMW, Mercedes, Audi, Volkswagen, Porsche, Honda, Dodge and others.

Consider service after the sale, too. Does the manufacturer have the total solution for your needs now and in the future? Also, do they have training and world representation, as automotive platforms are shared here and abroad?

Signature and Star-A-Liner

Signature and Star-A-Liner

Whether you’re looking to purchase your first frame machine, replace an older one or add an additional machine to your shop, the import thing is to look at its worth.

- Warranty – What type of warranty does the machine come with? What is included in the warranty?

- Opportunity – What type of machine will fulfill your current shop needs but also allow you to grow and expand?

- Reliability – Consider a quality machine that will be an investment for your shop and will be there for you when you need it.

- Time – How long does it take to make a pull? How much manpower is needed to set it up and operate it?

- Hydraulics – What are the pulling capabilities of the hydraulics? Are they run by air or electricity? Where are they manufactured?

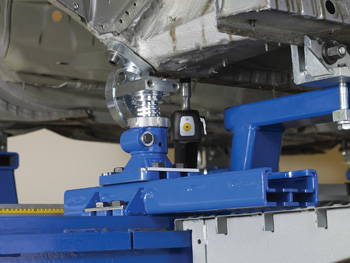

Spanesi

Spanesi

First and foremost, what type of vehicles are you repairing? This can limit the equipment capabilities or even the brand if you’re an OEM-approved facility. Or, if you’re in “truck country,” you may be in need of something totally different than shops in areas where automobiles are more prevalent.

With vehicle changes ever constant, so too is the evolution of frame equipment and today’s vehicles, which will require fixturing to facilitate repairs and holding. Now and in the future, pinch weld flanges can no longer support the vehicle and/or pulling forces. Fixturing, whether dedicated (vehicle specific) or universal (one system fits all) are necessary to hold the vehicle and the parts being replaced or repaired.

Is the equipment “user friendly” for the technician to help in cycle time reduction? With the average repair not always having heavy structural damage, smaller, multiple-use workstations or “multi-benches” are becoming more popular and give the technician a better working cell and increase efficiency by getting the work up off the ground to a good working height. The ability to measure the vehicle should exist as being to make pulls. Last, look for service, support and ongoing training – all supported both nationally and locally.

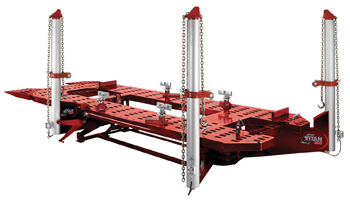

Chief Automotive Technologies

Chief Automotive Technologies

When shopping for a new frame rack, repair professionals must first determine what kinds of vehicles the rack will be used for. For facilities that service trucks, SUVs and other full-frame vehicles, it’s important that the frame rack has sufficient pulling power at each tower, a long deck and enough lifting capacity to raise the vehicle to a comfortable working height. Some systems may use powerful 10-ton rams, but the actual power at the hook may be as little as 4 tons. The Titan 360 frame rack from Chief Automotive Technologies features 10 tons of pulling power at the hook.

Car Bench

Car Bench

It’s time to look at benches that offer laser measuring and universal jigs. Full-frame clamps used with universal jigs provide rigid anchoring to replace blocks and chains for pulling sway, mash, sag, twist or diamond. Laser measuring systems update constantly as damage is pulled, and offer smart targets with LED lights showing the updates without looking at the computer. Unibody damage repair can be carried out using the same universal jigs with manufacturers’ data for a zero tolerance repair. Universal jigs can be built up for holding also, eliminating the need for multiple pulling towers.

Celette

Celette

When purchasing any new frame equipment for your facility, there are a few things to consider:

- Versatility – A frame machine that can handle any small repair to major, structural uni-body repair, as well as full-frame vehicles such as a pickup truck.

- Know Your Facilities – A bench with a built-in lift can make accessing under the vehicle more comfortable and save space. Likewise, verify if your new equipment manufacturer offers multiple pulling options and fast anchoring that’s adjustable in length, width and height.

- Material Developments & Repairs – Automakers from around the world are developing today’s vehicles with materials that don’t lend themselves to the simple pulling methods used in years past. A dedicated fixture system will hold a vehicle at specific control points that are dimensionally correct and accurate, while physically showing the amount of movement any damaged point needs in order to be corrected before a section can be replaced.

Wedge Clamp Systems

Wedge Clamp Systems

Look for a system with quick setup and multiple pulling options (5-, 10-, 15-ton) that can handle sub-compacts to full-size pickups. Also, look for a piece of equipment with a small footprint. With shop space at a premium, and most repairs being light hits, quick turnaround of more vehicles is critical.