Sponsored By:

Battery-electric vehicles (BEVs) and hybrid-electric vehicles (HEVs) currently account for 7% of the vehicle population in the U.S. — which means it is likely sooner rather than later that you’ll encounter one at your repair facility. But maybe you think you’ll be able to successfully dodge EVs for now. Good luck …since growth is expected to be 30 to 35% nationwide in the next seven to 12 years!

Risks

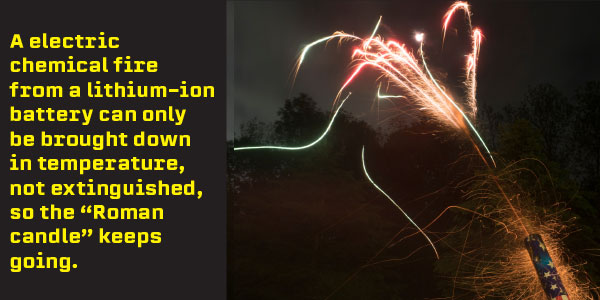

EVs have been making big headlines regarding the risk of fire, but the reality is that there are far fewer fires with EVs percentage-wise than with traditional internal combustion engine (ICE) vehicles. It’s just that the consequences of a thermal runaway in an EV are much greater than a fire event in an ICE vehicle. One of the challenges is that high-voltage (HV) battery fires are extremely hot, and nobody wants to experience that in their repair facility. The second thing is a electric chemical fire from a lithium-ion battery is hard to suppress and can only be brought down in temperature, not extinguished. So the “Roman candle” keeps going — and it is not going to be a pretty sight inside your shop.

Vehicle Intake

To avoid any surprises before, during or after the repair of a BEV or HEV, you must have an established vehicle intake process — which means you must be trained on safety and technology and committed to showing up and suiting up!

Let’s start when the tow truck arrives at your facility and the operator is about drop the vehicle off. Just like a regular vehicle, you want to make sure there is no gasoline or diesel fuel leaking from the vehicle. However, BEVs and HEVs are different because electricity does not show its face until it’s too late!

While unloading the vehicle, make sure the tires do not spin, as spinning tires will make the electro motor turn into a generator/alternator/dynamo, which can introduce an electrical charge in the “malfunctioning” HV system. If the HV system has been compromised by the accident, there could be severe consequences.

Risk Assessment

When the vehicle is dropped off, a risk assessment must be performed to determine if the HV system is safe. The main question is: Does the HV system need to be disconnected from the HV battery?

For example, when HV components are compromised by the accident and the system stays live, there is a high risk of a short circuit, thermal runaway and electrocution. It’s important to realize that when communication between the low-voltage system, HV system and the internal vehicle is intact, the HV system could be become live for a lot of reasons, one being thermal management. For example, if the vehicle is outside and it’s an extremely hot or cold day, those extreme temperatures will trigger the system to cool or warm the HV battery. To activate the cooling and heating system, it’s necessary for the HV battery to close the internal contactors to distribute high voltage to the electrical air conditioning compressor or heater. The goal is to cool the coolant fluid and run it through the battery pack, which means, on the other end, the HV system will be live — which could be dangerous if one of the HV components has been compromised by the accident.

The reason for conducting a risk assessment is that you want to mitigate the risk and reduce the potential for a thermal runaway — because there is no worse scenario than a fire inside your repair facility.

To perform a risk assessment, you must be aware of the architecture of the inspected vehicle’s HV system and where HV components and cables are located. You need to compare the crash impact on the vehicle with architectural drawings and, when a component is compromised, you must disconnect the HV battery from the system. On the other hand, when the system is not compromised, you still must determine if it’s better to leave the system live for thermal management or not. To make this decision, you need more information and data from the vehicle and battery.

There are two great resources you can use. The first one is the Risk Assessment Service from the Energy Security Agency (ESA). The ESA has developed a risk asssessment app that is available for download right onto your smartphone for easy access. The process is pretty straightforward in that all you have to do is enter the vehicle information and snap seven pictures of the vehicle. The app is equipped with many things, including vehicle HV architecture drawings and AI information. From there, the up-to-date database will help you determine if an HV component has been compromised. Users will receive a report and a determination of the current risk. If you prefer not to use the app, the ESA operates a 24/7 technical hotline as well, where an engineer examines critical cases and helps determine the risk assessment. You can reach the ESA Guidance & Response Center by calling (855) 372-7233.

Another great resource is the EV Rescue app. This app will give you access to vehicle manufacturers’ emergency rescue guides (ERGs). In the ERGs, you can get information on the location of HV components and where the HV disconnect is located.

HV Disconnect

When an HV disconnect is to be performed, you must wear proper personal protective equipment, such as HV Class 0 gloves, leather protection gloves and arc flash helmets. Also, only a technician educated and trained on HV safety should perform this task.

Unfortunately, the risk assessment is still not complete even when you determine that there is no damage to the HV system — because the HV battery may have sustained concussive damage. Concussive damage occurs when the deceleration force (G-force) during impact is so high that the battery cells get damaged.

To detect a cell failure as described, it’s recommended to use a thermal imaging camera (TIC) as well as a carbon monoxide (CO) or four-gas meter. When there is a chemical reaction within a cell, the cell will start to develop temperature and produce several gasses which will “off-gas.” The TIC can help you see this temperature production within the cell, but unfortunately, when this is visible, that means there is already a lot of temperature present and the vehicle must be immediately isolated and the fire department notified.

The gasses that will off-gas include a mix of carbon monoxide, carbon dioxide, hydrogen and hydrogen fluoride. Those gasses will off-gas in an early state and will leave the battery enclosure over the internal venting system. It is recommended to use a CO or four-gas meter to measure and detect if there is any CO around the battery enclosure. CO is, of course, not natural to an EV, which means that when any CO is detected, it raises the question: Where is it coming from? A threshold of 25 to 35 parts per million of CO production out of the HV battery will trigger a further investigation, which can result in vehicle isolation and a call to the fire department.

It is also recommended to equip your facility with CO monitors in the EV repair space. The monitors must be placed in a five-foot area around the HV battery and at the height of the battery. Keep in mind that the gasses that are off-gassing are a bit heavier than air and will flood around the vehicle and not go up to the ceiling.

The current recommendation for a vehicle isolation zone from the National Highway Traffic Safety Administration is 50 feet of clearance from any building or vehicle or anything combustible. This is a lot of space that not many professional repair facilities have available and, for this reason, the ESA has developed architectural drawings for affordable beam block isolation construction.

Diagnostics

Another important step in determining risk in a BEV or HEV is a comprehensive diagnostic check via a manufacturer’s diagnostic tool. When it’s safe to switch on the 12-volt system (push start button while not pushing the brake pedal), you would connect the diagnostic tool to the vehicle and perform a HV battery diagnostic check. The goal of this procedure is to determine the state of the battery’s health and check state of charge (SOC), contactor position/function, temperature sensor information and how all battery cells are balanced to each other. If this all looks good, we can then get the vehicle into your facility and start the repair process.

Battery Coolant Leaks

Another important test for the HV battery that is rarely — if ever — done involves battery coolant leaks.

Most battery problems I see in the field are battery coolant leaks or battery enclosures that are not sealed, where moisture can come into the battery and cause a thermal runaway, causing a “silent death.” These problems can occur after an accident and the high deceleration force, which can cause a leak in a coolant line or battery enclosure.

This is the reason why coolant and enclosure testing must be performed during the repair process to gauge the integrity of the system. More and more manufacturers are releasing position statements describing exactly when this test must be performed, so make sure to read the manufacturer position statements on this topic. Every manufacturer’s procedure is slightly different, as some perform the test while applying air pressure while others use a vacuum. The goal is to learn if any pressure or vacuum loss is present, indicating that the system is leaking and must be repaired immediately. I-CAR worked with Redline Detection to create a Repairers Realm episode on this important topic, and you can access it here.

OEM Standards

Lastly, remember it is of utmost importance that, when a vehicle sustains a collision, the total integrity of the vehicle and its HV electrical system is repaired to OEM standards. Always follow manufacturer standards, keeping in mind, however, that there will be a flood of information and also a shortage of information in the transformation of vehicles to this energy propulsion.

As it says in the headline of this article, “It all starts with the intake process.” And, it is all about the proper knowledge and skills. Please educate yourself before you start working on these vehicles.

To view our full EV Guide from the January 2024 issue, click here.