Opportunities to spark gains in key-to-key productivity lie in the mixing room where digital advancements recently introduced by PPG are proving to save time, reduce waste and improve color-matching accuracy. The PPG LINQTM digital ecosystem is comprised of interconnected hardware, software and innovative services, using a cloud-based platform.

PPG DIGIMATCHTM Spectrophotometer

This compact spectrophotometer takes readings of a vehicle’s color from six imaging angles as well as six reflective angles to provide color and texture information—including effect pigment particle size. Its lightweight, small form allows users to take accurate readings even on curved surfaces, with readings taking less than 30 seconds.

The color reading is then seamlessly loaded into PPG retrieval software to find color formulations providing the best match. The spectrophotometer’s readings work in concert with another PPG innovation to further enhance the ability to determine the best match—PPG VISUALIZID™ software.

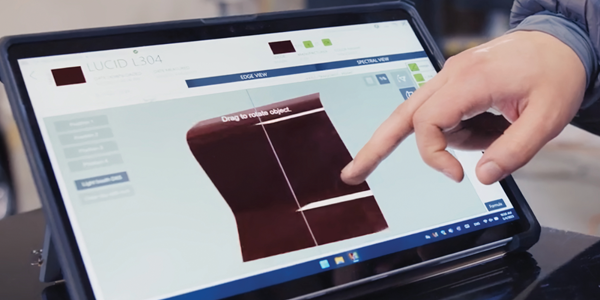

PPG VisualizID Software

The first of its kind in the industry, this digital color visualization tool works with a PPG spectrophotometer to enable the technician to compare realistic 3D renderings of the retrieved colors and determine the best color variant from PPG’s extensive color match library.

Technicians can compare multiples of these “virtual sprayouts” in a matter of minutes. Each sprayout can be compared from flash, flop or face angles, rotated in any direction as well as from “blend” and “edge” views.

“In the old days, we would have to do our own sprayouts to test the colors,” explains Carl Garcia, owner of Carl’s Collision Center, Fall River, Massachusetts. “It would take us a minimum of 15 minutes for each car, sometimes over an hour. So now instead of having to do sprayout cards, we are able to do a virtual sprayout.”

Once satisfied with the match, the technician can hit a button to send the formula to another PPG innovation that Garcia’s operation has incorporated into their process—the PPG MOONWALK® mixing system.

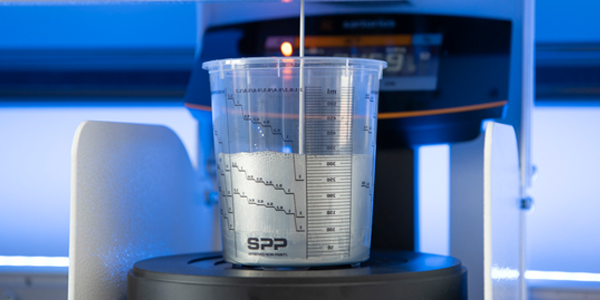

PPG MoonWalk Mixing System

Designed for PPG ENVIROBASE® High Performance toners, this automated mixing system replaces the manual mixing process with a self-contained system that eliminates spills and achieves extreme mixing accuracy.

Creating a color mix is simple and straight forward. Once the technician retrieves the matching formula from PPG’s PAINTMANAGER® XI software, the technician loads the required toners on a dispensing rack. With one click, the PPG MoonWalk system takes it from there. First, it double checks barcodes to ensure the right toners are loaded. The system then automatically dispenses the exact amount of each toner—at an accuracy ten times more precise than the standard. To further eliminate waste, the system is designed to ensure all of the product is used, down to the last drop.

“One of the most obvious differences is that it mixes to the hundredth—not to the tenth—so it’s much more accurate with the color match,” explains Frank McClosky, owner, McClosky’s Collision Repair, Baytown, Texas. “When the painter has full confidence knowing that the color is going to match the first time, there’s no need to mix extra paint that you might need to tint.”

“This is a great advantage for us,” echoes Garcia. “It’s 100% accurate. No waste. And it has increased our efficiency by at least 15%.”

Garcia adds that the digital tools he’s incorporated from the PPG LINQ ecosystem are especially advantageous given his primarily younger team. “These kids today grew up with computers, with smartphones—it’s a totally different mentality. So we need to adapt to the changing workforce.”

Given that paint shop throughput is an important KPI, these PPG innovations can significantly contribute to maximizing key-to-key productivity. For more information on the PPG LINQ digital ecosystem and MoonWalk automated mixing system, contact your local PPG distributor or sales representative.

Sponsored by PPG Industries.