In-house ADAS calibrations means safety, efficiency, and profitability for collision shops. Control the process and reap the benefits. Learn more in this six-part series.

Advanced Driver Assistance Systems (ADAS) is an umbrella term for the multiple vehicle safety and convenience systems becoming increasingly common on today’s vehicles.

Blind Spot Warning (BSW), Lane Departure Warning (LDW), Automatic Emergency Braking (AEB), and Rear Collision Warning (RCW) are the core systems. This year, more than 60% of registered vehicles in the U.S. will be equipped with ADAS, according to the Insurance Institute for Highway Safety estimates. That’s 180 million vehicles.

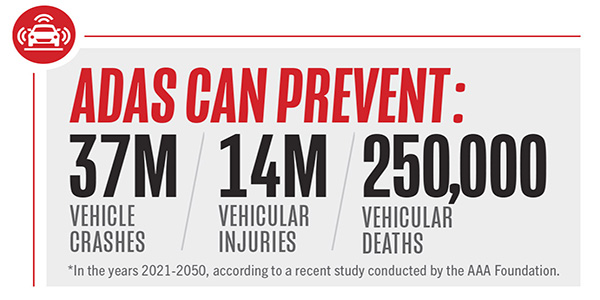

Consumers and regulators alike cite safety as the primary reason for soaring adoption. Studies show that in the 30 years from 2021 through 2050, ADAS technologies currently available to U.S. consumers could prevent approximately 37 million crashes, 14 million injuries, and nearly 250,000 deaths—that’s 22% of deaths that would otherwise occur on U.S. roads without these technologies.

Always on the frontline of servicing vehicles with the latest technologies, collision shops are aware of the growing popularity of ADAS-equipped vehicles. And though it might have been standard or even best practice to sublet ADAS work to dealers or to mobile solutions when ADAS-equipped vehicles started to trickle into collision shops, more body shops are realizing that performing ADAS calibrations in-house optimizes their key-to-key cycle time—giving them greater control of the shop operations and the quality of the vehicle repair—and can drastically increase profitability.

A recent AAA study found that ADAS repair and calibration account for 36.7% of collision repair. Given that percentage and the number of ADAS-equipped vehicles that collision shops repair today and will repair in the future, keeping those calibrations in-house is a significant financial opportunity.

This series aims to illustrate that reward is within reach, and we would like to show you how to get it.

But first, let’s briefly examine the ADAS industry environment and the challenges therein.

Automakers have marketed these systems with unique names and often have bundled systems into suites. Honda, for example, trademarked its AEB system as the Collision Mitigation Braking System and called its suite of seven systems HondaSensing. Meanwhile, the Mercedes-Benz Intelligent Drive suite offers up to 23 systems, with variations of AEB dubbed Active Brake Assist/Active Brake Assist with Cross-Traffic Function, Collison Prevention Assist Plus, and Active Emergency Stop Assist.

Indeed, when technicians calibrate these systems, they should familiarize themselves with how they are intended to behave and confirm this correct behavior in the post-calibration test drive. But, regardless of what the automakers call them, when it comes to ADAS calibrations, we are speaking about the sensor components, such as cameras, radar, and lidar.

Depending on the system design, these sensors act independently or together (the technical term is sensor fusion) as input devices to prompt “action” in these systems. That action, whether passive or active, depends on that system’s design for that vehicle make, model, and year. Simply put, Passive systems “alert” and Active systems “act.”

Let’s take a look at the typical Lane Departure Warning system. These systems use a camera near the rearview mirror that detects lane markings. Suppose the vehicle moves out of its lane without the driver activating the turn signal. In that case, the system will “passively” alert the driver with visual, audible, or haptic feedback (the steering wheel vibrates). Similar to LDW is Lane Keep Assist (LKA). This system uses the same rearview mirror-situated camera to detect lane markings. But with an LKA system, if the vehicle crosses the lane markers, it will act to center the vehicle within the lane. How the vehicle does that—what other vehicle systems it enlists to perform this operation—depends on the system design. Some systems apply torque to the steering wheel, while others apply pressure to the brake. Most new vehicles use LDW and LKA.

Next, let’s take a look at Automatic Emergency Braking (AEB). Quick history lesson: AEB is the second ADAS function to be required on new vehicles. Rear cameras were mandated on new vehicles in 2018, and AEB will be required on 95% of all brands’ light vehicles starting September 1, 2024, and across all brands’ products, including 8,000 to 10,000-lb. vehicles beginning September 1, 2025. AEB systems have evolved from being radar or camera-based to combining both. Yaw rates and latitude and longitude monitoring of the vehicle traveling in front influence how this system works. But simply stated, the typical AEB system detects an imminent collision, alerts the driver and acts to avoid the collision by applying the brakes. AEB elicits the help of the Anti-lock Braking System (ABS) and wheel speed sensors to avoid collisions.

We will revisit this topic later in the series, but it’s essential when discussing taking on ADAS calibrations to adjust our approach to vehicle repair, from blinders-on parts and component replacement to an all-vehicle, all-systems mentality. No man is an island, and no vehicle system is one, either. The electrical system on today’s vehicles features multiple communication networks with well over 100 control modules with multiple sensors and actuators within. The designs are interconnected and rely on each other to complete the job.

The next part will examine what a shop needs to get started with ADAS calibrations, shop size, layout, and how the Autel website-based Return-on-Investment calculator can determine what calibration system best suits your shop.