Many legislative and environmental mandates have affected the collision repair industry over the last decade. To comply with such mandates, vehicle manufacturers continue to design vehicles with increasingly advanced electronics, ranging from Advanced Driver Assistance Systems that increase safety, helping people with everything from parking to driving, to the recent push for electric vehicles. They’ve also moved to lighter weight substrates, which may require new products to repair. Combine all these technological advancements along with the recent parts and product shortages and increased acquisition costs, PBE distributors and collision repairers alike have had to adapt their businesses to stay afloat.

While electronic parts shortages are not replaceable, our industry has shifted away from more commonly replacing damaged parts to repairing them, when feasible. Every day North American body shop technicians incorporate multiple repair processes to correct collision damage in the most efficient manner. Methods and tools that streamline workflow, reduce cost and complexity, and free up personnel are critical to a successful operation. One such method includes incorporating high performance products to better manage small repairs, reduce costs, and simplify the process due to a shrinking base of qualified technicians:

Small Gouges on Plastics

Some manufacturers’ offerings require technicians to first identify the type of substrate and then use a substrate-specific material to make non-structural repairs. There are other products on the market which eliminate the plastic identification requirement because they are compatible with multiple substrates so distributors and collision repair shops can stock less products.

Small Dents, Scratches and Surface Imperfections on Metals

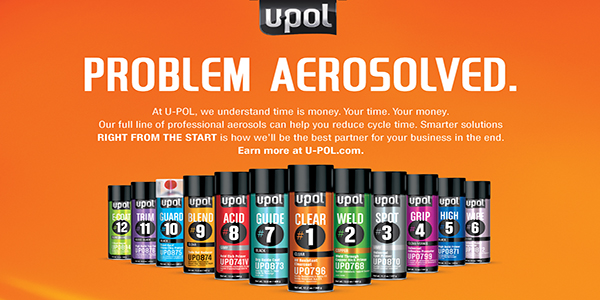

Historically, after non-structural repairs were made, there used to be a certain stigma tied to using aerosol products in the shop. Aerosols were considered “DIY” products that didn’t meet the standards of the professional body shop technician. While we have many challenges on our hands in our current environment, today’s generation of aerosol products offer many benefits for the distributor and shop. With so many options on the market, distributors can offer a compact set of aerosols, which will be used in shops’ everyday processes. Today’s aerosols are available in 1K and 2K configurations, and feature enhanced atomization and a comparable fan pattern and finish to spray guns. When used for localized spot repairs, aerosols also help control VOC emissions and maintain compliance under increasing state and local regulations. Before the development of these advancements, all coatings repairs were traditionally handled by painters in a spray booth. Fast forward to today, and junior shop technicians can complete repairs outside of the booth, helping to free up the painter and spray booth, while also helping to control cost, and drive more profits per repair.

While there have been strains on supply chain, there are solutions to help manage what can be controlled. And with the right set of tools, anything is possible.

This article is sponsored by U-POL. For more information, click here.