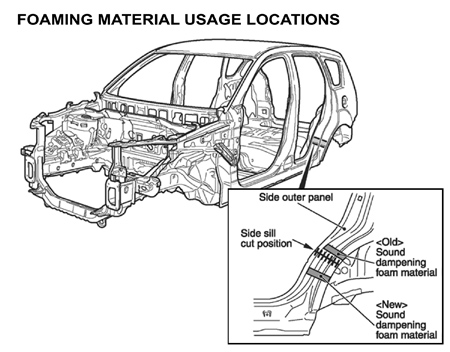

Sound deadening material can be critical to a repair. This material is incorporated in today’s vehicles to dampen vibrations and sound, not to mention provide structural support in some cases. Without prior knowledge of the location or types of material, your team may not be incorporating additional procedures or charges on repair plans. And your technicians may not know how to identify the type of material or its proper replacement procedure. This tech tip for the Mitsubishi Outlander describes the revised placement of the sound dampening material for the side sill, inner and outer quarter panels (Figure 1).

Sound deadening material can be critical to a repair. This material is incorporated in today’s vehicles to dampen vibrations and sound, not to mention provide structural support in some cases. Without prior knowledge of the location or types of material, your team may not be incorporating additional procedures or charges on repair plans. And your technicians may not know how to identify the type of material or its proper replacement procedure. This tech tip for the Mitsubishi Outlander describes the revised placement of the sound dampening material for the side sill, inner and outer quarter panels (Figure 1).

Applicable Model

2007 Mitsubishi Outlander built on or before March 1, 2007.

Required Part

Flexible Foam – 3M 08463

Service Information

Always refer to ALLDATA Collision for safety procedures, identification of material types, recommended refinish materials, and removal and installation procedures. Always refer to Mitsubishi for questions relating to applicable or non-applicable warranty repair information.

Installation

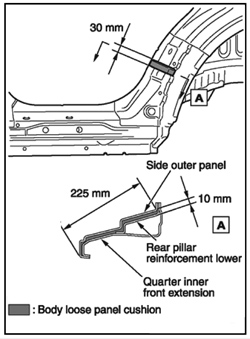

When installing the new floor side sill outer, the inside of the wheel arch cannot be filled with sound dampening foam material. Therefore, machine the body loose panel cushion (MR435765 or MR65301) shown in Figure 2 as an alternative and adhere it.

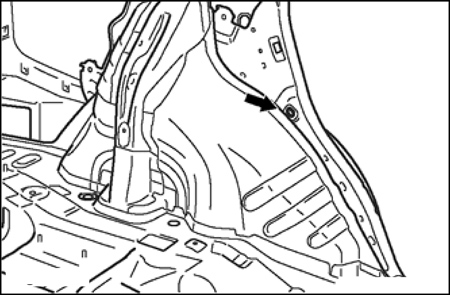

After installing the floor side sill outer, seal the hole and flange with a bolt and aluminum tape, and then fill the hole with the sound dampening foam material as shown in Figure 3.

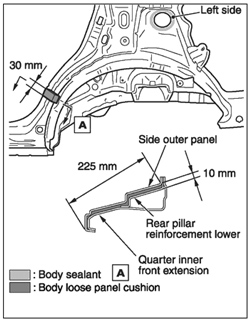

Quarter Outer – The position and the size of the body loose panel cushion that’s installed when installing the rear quarter outer panel have been changed (Figure 4).

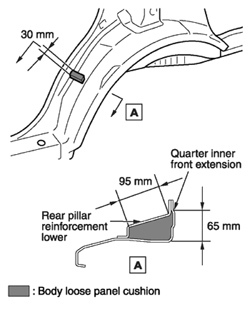

Quarter Inner – The position and the size of the body loose panel cushion that’s installed when installing the rear pillar reinforcement lower have been changed (Figure 5).

Dan Espersen is the ALLDATA Senior Collision Program Manager. He’s a Gold Pin Member of the Collision Industry Conference (CIC) and holds an AA Degree in Automotive Technology. He has 17 years of experience in the collision industry and 17 years of experience in the automotive industry. © 2008 ALLDATA LLC. All rights reserved. All technical information, images and specifications are from the ALLDATA Collision. ALLDATA is a registered trademark and ALLDATA Collision is a mark of ALLDATA LLC. All other marks are the property of their respective holders. Mitsubishi and Outlander are registered trademark names and model designations of Mitsubishi Motors North America, Inc. 3M is a registered trademark of 3M Company. All trademark names and model designations are being used solely for reference and application purposes.