No matter where your collision repair facility is located, advanced materials like composites, high-strength steel and aluminum are in your future. Not only do repairs of these materials require specific processes and equipment, you may need OEM certifications to handle repairs on some vehicles.

Planning Ahead

At my three CARSTAR locations in Sidney, Troy and Piqua, Ohio, we dedicate time and resources to plan how we will repair vehicles in the future. Right now, we see a lot of Ford pickup trucks with aluminum beds. We’re located in a rural area, so we were able to anticipate and plan for this. When the vehicle was first introduced, we began planning for aluminum repair, which included training and securing the proper equipment and workspace.

Analyze Your Market

As we look at the new vehicles for 2020 and beyond, we are evaluating what we might see in Ohio. We probably won’t have many Teslas or Audis, but I’m sure we’ll see the new Ford Explorer, Jeep Gladiator, Toyota Corolla, Hyundai Sonata and Honda CR-V on our streets.

It’s important to make sure you’re planning for your specific market as consumer preferences and needs vary greatly. This can help you focus in on the exact equipment you need, the technician training required and what OEM certifications to pursue.

My Method

If you aren’t sure how to get this information, here’s my approach:

- I keep a running mental list of what I see on the road in the communities where my facilities are located.

- I read the consumer car magazines to see what the hot new models for the year ahead will be.

- I talk to colleagues at auto dealerships about what they’re selling and who’s buying them.

- I check with local insurance agents about the new cars they’re insuring.

- I tap into my paint partner BASF’s market research.

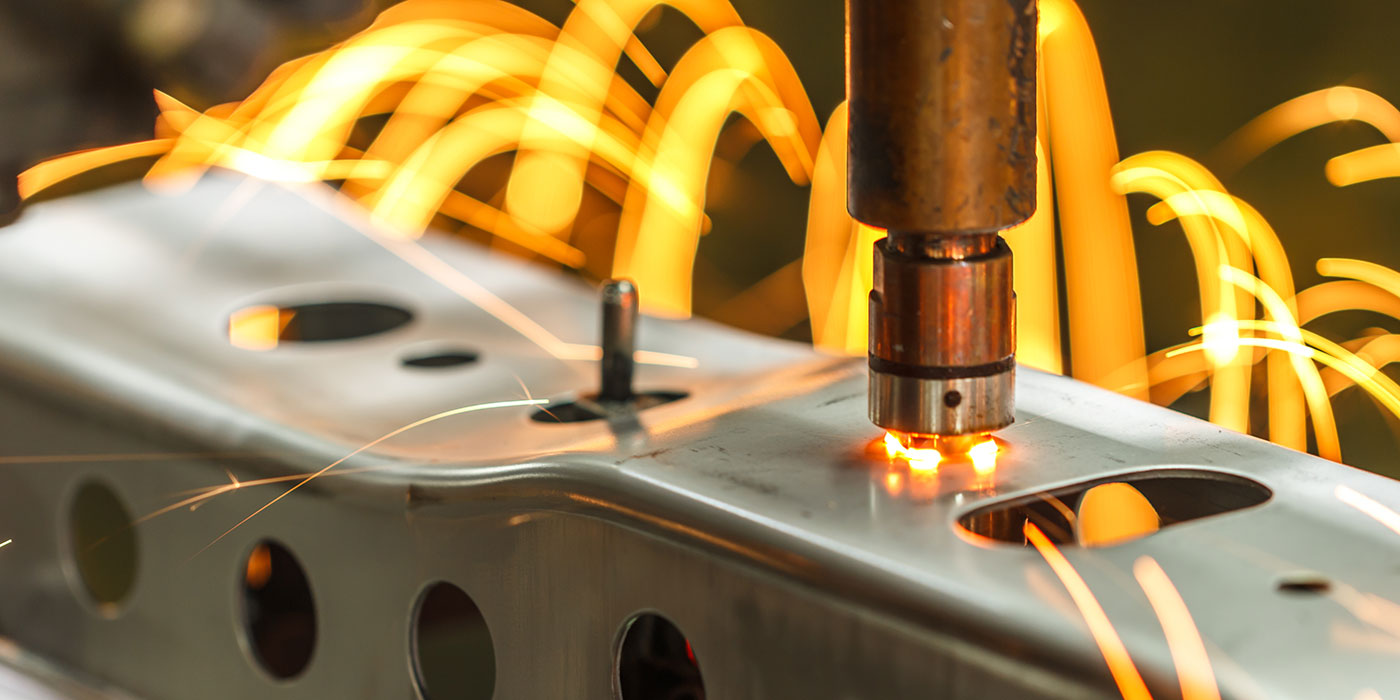

- I research what it will take to repair these vehicles to meet the insurance DRP and OEM standards. This helps me plan for what equipment I need to purchase or upgrade so I can then start saving for that investment. When you’re evaluating the purchase of a $30,000 welder, it’s important to understand how you’ll recognize the returns on that investment.

Training/OE Certification

Researching vehicle trends in my market also allows me to determine what training my team will need. Being a part of CARSTAR is a tremendous asset on this front. They regularly gather all of the needed training requirements for the different OEM programs and share them with the network. They also provide online training through CARSTAR University and hands-on training with vendor partners around the country. Our Sidney and Troy stores are certified by Honda as ProFirst shops.

This preparation helps guide our approach to OEM certifications. Achieving these certifications takes time and resources, so you want to make sure you’re getting the ones that are most beneficial for your shop. And once you have them, it’s important to promote your OEM repair certification to customers in that marketplace who are driving those vehicle makes.

Finally, I talk with other CARSTAR owners around North America about how they’re handling repairs for advanced materials. Having a family of more than 700 locations to call on is a huge benefit!

So, while my three CARSTAR locations are focused on aluminum repairs today, along with traditional materials, we’re preparing for the future of composites, high-strength steel and other alloys that will soon be appearing at our door.

Tom Martin is the owner of three CARSTAR locations in Ohio – CARSTAR Sidney, CARSTAR Troy and CARSTAR Piqua. He started working in a collision repair shop at 15, then went on to purchase the business. He joined CARSTAR in 2003 with his first location. He opened his second CARSTAR location in 2014 and a third in 2019. He has long been a champion of advanced technology and also training for his team. He also donates his time to a variety of volunteer organizations, veterans in need, the homeless and youth sports. He can be reached at [email protected].