It’s 2 p.m. on a Friday afternoon. Mrs. Brown’s car is a couple days late, but it’s scheduled out at 4 p.m. It’s a good thing it’s going because payroll and taxes have drained the bank account and that $4,500 from Mrs. Brown will help the world turn another day.

It’s 2 p.m. on a Friday afternoon. Mrs. Brown’s car is a couple days late, but it’s scheduled out at 4 p.m. It’s a good thing it’s going because payroll and taxes have drained the bank account and that $4,500 from Mrs. Brown will help the world turn another day.

That’s when Brian, the metal tech who’s working on Mrs. Brown’s car, walks into the office holding a small broken part and says, “Hey Boss, I need one of these to mount the headlamp in Mrs. Brown’s car. You want me to wait for it or should I just go home?”

Sound familiar? Sadly, in many collision repair facilities, last-minute parts problems, supplements and repeated interruptions of the repair cycle are commonplace.

Every day, it seems as though someone has a new and improved process to boost profit for the body shop. Trade magazines and management seminars tout new concepts and ideas to make more money and reduce cycle time. They all sound great and, believe it or not, they work. But back in the real world of collision repair, with real cars and real insurance companies and their adjusters, things move a bit slower.

So, what can real shop owners, managers and estimators do today to increase sales and improve efficiency while at the same time reduce supplements? Is there such a magic process?

No Hocus Pocus

It’s not magic, but simply spending more time creating a complete and accurate damage evaluation results in more money, faster repairs, reduced headaches and improved efficiency. This process is called “blueprinting” the repair.

We need to look no further than the front of our own shops to see how our damage evaluation processes cause us problems. The customer comes in asking for an estimate, we write the estimate in the parking lot, order parts and begin dealing with the insurance company. Sometimes, the drive-in insurance adjuster writes the estimate in the parking lot, the customer brings it in, and we order parts and schedule the repair.

In either case, the problem is that the estimate was written in a parking lot. Our supplement ratio provides stark testimony about the efficiency of the current standard estimating practice. Once the vehicle arrives for repair, the technician begins working, then stops to make a list of operations and parts that were missed on the initial estimate. The job is put on hold for insurance approvals and supplemental parts orders. Wasted technician time, increased estimator workload and production inefficiencies are the result. Oh yes, the last-minute missing part problem is buried in there somewhere, too.

Details, Details

In construction, a blueprint tells a contractor and his workers exactly how to build a house or building. Everything is spelled out or drawn in detail. Each of the individual workers can see exactly what he or she is supposed to do by reading the blueprint.

Blueprinting a collision repair is simply creating an estimate that’s so detailed that the technicians who repair the vehicle can see exactly what they’re supposed to do and exactly what’s needed to repair the damaged vehicle. Every part, clip, material and operation is listed in the blueprint. Not included P-page operations should also listed, even if they’re not going to be paid for by the insurance company or the customer.

A blueprint is much more than an estimate – it’s a complete and accurate representation of everything required to restore the vehicle to pre-loss condition.

For example, there would be a big difference between an “estimate” for blending a door and a blueprint for the same procedure. The estimate is quick to write, only three line items. Compare that to a blueprint for the same operation, which might have 10 lines and include the required clips and materials needed for the blend operation. In a real-life blueprint I saw, the itemization of required operations resulted in increased parts sales of $15.46, increased miscellaneous materials sales of $3.50, 0.7 additional body labor hours and 0.2 additional paint hours and paint materials.

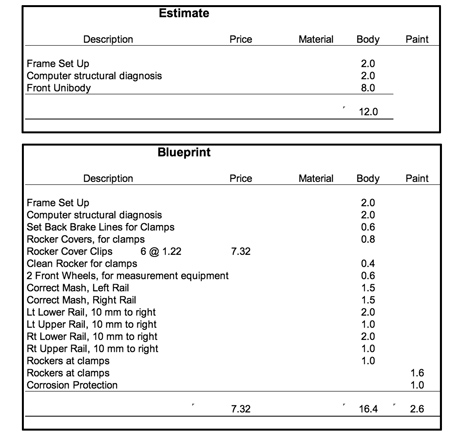

Figure 1 (above right) is an example of a frame repair “estimate” compared to a more detailed blueprint. The estimate has three lines of labor associated with the structural repair, whereas the blueprint has 16 lines and results in 4.4 additional repair hours, 2.6 refinish hours and $7.32 in parts that weren’t included in the estimate.

It’s easy to see the difference between an estimate and a blueprint by looking at the examples. The blueprint provides a detailed, line-by-line road map for repair. The estimate is exactly that – an estimate.

Common sense tells us that if we would just write a complete and accurate damage analysis, vehicles would be repaired faster with fewer interruptions and supplements. Also, shops, estimators and technicians would be better compensated for the work performed. We all seem to know that. So why do we continue to work from estimates?

Why Write Estimates?

The estimates just discussed could have been written by adjusters or shop estimators. They could have been created under a DRP or for a drive-in estimate. And we see them every day.

In seminars, I’ve asked the question, “Why write estimates?” The answers are usually the same:

• to place a value on the repair;

• to determine if the car is repairable;

• because the customer asked for it;

• the insurance company required it;

• to sell the job; and

• to tell the technician what to do.

So we write estimates for a variety of legitimate reasons, but problems arise when we try to repair the vehicle according to the estimate. To write a complete and accurate damage analysis, or blueprint the repair, we should understand that the damage analysis should be part of the repair, not the sale. Shop estimators should focus on selling first and damage analysis second.

There are times that writing an estimate is required. But if we try to sell first, then perform the damage analysis, we’ll be in a better position to create a blueprint. Repairing the vehicle from a blueprint will result in reduced cycle time and improved compensation for all involved.

Blueprinting 1-2-3

Creating a blueprint requires three distinct things: an estimator, a knowledgeable technician and a signed repair order.

First, the technician is required to tear down the vehicle, which is why we need the signed repair order. The vehicle should be dismantled to the point where a qualified technician can see all damage – an important step since it’s imperative to find the “hidden” damage before repairs begin.

Next, the qualified technician and the estimator should begin the crucial process of generating a complete list of all operations, parts and materials required to restore the vehicle to pre-loss condition. The technician and estimator should have conversations to make sure everything is listed. Moldings on blend panels should be removed to determine if clips are required. Don’t forget fluids, removal of urethane coatings and adhesives, welding damage and all of the other little things that will add up to a lot of paid operations.

This discussion is critical to producing the blueprint. I suggest using a yellow legal pad to make the list of parts, materials and operations. Discussions regarding labor time can bog down the process, so avoid them. Just get everything written down.

Once the list of required operations, parts and materials is completed, the estimator should create the blueprint. Don’t lump operations together. Detail everything, list all clips, materials, fluids and operations, line by line. Order parts from the blueprint, and repair the vehicle by the blueprint.

A Better World

While our world may never be perfect, it will improve if we blueprint repairs to find unseen damage and parts prior to beginning a repair.

Blueprinting will result in reduced cycle time, improved compensation, improved CSI and increased sales.

Writer Hank Nunn has been involved in the collision repair industry for 30 years as an adjuster, shop owner, technician and consultant. Nunn is president of H W Nunn & Associates, a collision industry consulting firm. He’s also the lead facilitator as well as sales and marketing manager for DuPont Performance Coatings SMART Management Seminar Series. Nunn can be contacted at [email protected].