PPG’s expanded virtual learning options enable collision shop personnel to learn at their own pace and chosen time.

Historically, collision repair training has been conducted offsite at an instructional facility, providing hands-on, interactive learning from instructors and peers. The challenge for owners and managers, however, is finding the opportune time for an employee to take part in offsite training without significantly impacting the business. The COVID-19 pandemic further impacts both offsite and onsite training opportunities.

To address these issues, PPG’s Refinish Solutions team has expanded its training course offerings with a new “blended learning approach.” It’s comprised of three types of learning choices: live virtual, on demand and in person.

The team’s mission is to ensure that no matter what the customer training needs and preferences are, there will be a PPG solution to meet it.

PPG KNOWLEDGE COLLEGE™

The centerpiece of this initiative is the launch of the PPG Knowledge College, a self-paced learning management system. It promises to be the industry’s most comprehensive online training program for automotive and commercial finishing systems as well as for professional business development.

“The PPG Knowledge College program offers our customers great flexibility since it allows the student to decide when the best time is to undertake training and learn at their own pace,” explains Robb Power, PPG senior manager, refinish solutions. “All you need is a computer and access to the internet.”

Offering both free and fee-based content, the PPG Knowledge College training catalog includes courses for automotive and commercial refinish training as well as curriculum developed by PPG’s MVP Business Solutions team, to help improve the productivity and profitability of collision centers.

Automotive Refinish Recertification Training

In a major shift, the new learning management system now allows certified paint technicians using PPG’s DELTRON® and ENVIROBASE® High Performance refinish lines to recertify their status online, instead of attending off-site training at a PPG Business Development Center every two years.

The recertification course is comprised of seven one-hour modules, followed by a final exam that the technician is required to pass to complete the recertification.

“The beauty of this online course is that technicians will have the ability to restart or resume the training whenever they choose to do so,” Power says. “Plus, it offers a convenient way for collision centers to continue offering the PPG Limited Lifetime Paint Performance Guarantee, which requires they employ a PPG-certified refinish technician.

Refinish technicians can also take a course on the EPA National Area Source Rule 6H, available in both English and Spanish.

Business Solutions Training for Collision Repair

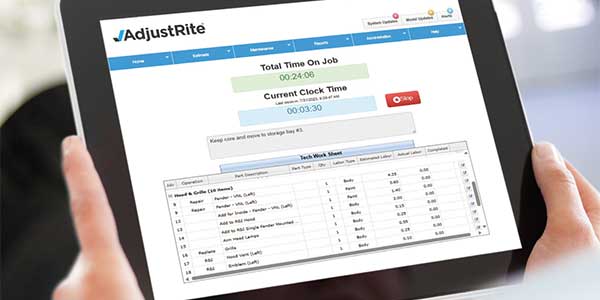

Once enrolled in the PPG Knowledge College, collision center personnel can take advantage of a comprehensive curriculum developed by PPG’s MVP Business Solutions team. The curriculum covers a multitude of collision repair topics in addition to offering two specific learning paths on Collision Shop Estimating and Collision Shop Financials.

Beginning with Fundamentals of Estimating, the estimating curriculum is comprised of seven modules, aimed to teach novices the key factors for producing complete and accurate estimates.

“We’re receiving great feedback on the estimating courses,” says Mike Gunnells, PPG senior manager for MVP Business Solutions. “They’re a great way to get a less experienced employee up to speed quickly as a productive estimator.”

The Collision Shop Financials curriculum offers five virtual learning sessions, primarily focused on helping managers improve upon the profit and loss and balance sheet. “This curriculum is specifically tailored to our industry, so it’s a great way for collision managers to improve their finance acumen,” says Gunnells.

If you’re a PPG customer interested in enrolling in the PPG Knowledge College, you can register at knowledgecollege.ppgrefinish.com. Training is available in English, French and Spanish for North American refinish customers.