I’ve heard that change is constant. With car manufacturers scrambling to meet the CAFÉ regulations, change will not slow down anytime soon.

A main focus we in the repair industry must keep through this change is the big picture, which is that cars need to be lighter yet stronger. This has led to the development of new steels we’ve never seen before. The engineering that goes into the manufacturing of these steels is crazy to most of us and beyond our grasp, but the why is not. Safety is the key. It can’t be just lighter, it must function as designed.

The New Trend

I’m going to give a lot of credit to I-CAR. The classes it has produced over the past few years are packed with information. The classes on steel and welding (SPS07 and WCSS03), along with sectioning classes (SPS10, SPS11 and FFR01), have prepared us for the new trend which many see as growing. To repair the new wave of construction materials, we must know that repair procedures of just yesterday could damage a car significantly.

A great example is Honda’s release of crash testing done on a 2014 Acura MDX that was repaired using MAG plug welds instead of squeeze type resistance spot welding (STRSW). Many saw this at the SEMA Show. During the crash testing following the Insurance Institute for Highway Safety’s parameters, the vehicle did not perform as designed and injuries would have occurred. The repairs were done to duplicate what a shop had done to repair this year, make and model of vehicle. Honda was trying to show the importance of following OE guidelines.

Honda/Acura

Honda released more information on correct repairs in their August 2016 Honda Body Repair News and also the inaugural issue of ProFirst Quarterly released in October, their new magazine geared toward promoting the ProFirst certified program and the complete and correct collision repair of all Honda and Acura automobiles. I encourage people to read these and understand that this will continue to be a major change in the way we look at repairing vehicles. Honda won’t be the only one outlining these procedures.

No longer can you just grab a GMAW (Gas Metal Arc Welder), set it and weld. You need to look into the manufacturer procedures to verify what wire and or what procedure you need to use specifically in the location you’re working on. Generalization is not allowed.

You’ll also need to learn that the terms mild strength steel and high strength steel, among others, are generalized terms. Also, that the repairability of the type of steel may be classified in megapascal (MPa), a metric pressure unit, versus the psi we’re familiar with. Manufacturers are now defining repairability based on the MPa of the steel.

The Honda procedures state where and what will be used to weld in specific areas. No longer is it just generalized. Honda tells exactly what weld goes where. With the previous mentioned crash test, Honda has proven they’re right in doing so. Honda wants their vehicles repaired right to protect occupants. A friend who works for a manufacturer (not Honda) once told me: “We have to build them safe. Dead people don’t buy cars.” This is a morbid statement but true. When doing a plug weld versus STRSW can determine whether injury occurs in a crash, we must take notice.

Wire Considerations

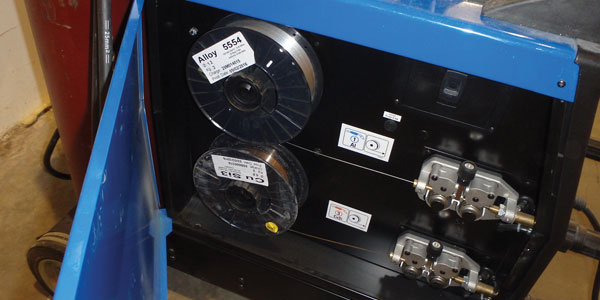

Wire matters. I-CAR has been teaching this for awhile, and Honda makes it clear. No longer is that ER70S-6 wire that we find in 99 percent of all welders in the U.S. correct. It may be correct for steels up to 440 MPa as the wire strength is 483 MPa (with ER70S-6, the 70 psi converts to 483 MPa). According to Honda, in the repair of high strength steels, the wire must be equal to or greater than the lowest tensile strength of the parts being welded.

Honda goes on to state which wire you should use and where a shop can find it. Bohler Union X96 (980 MPa) 0.8 diameter or approved equivalent must be used on MAG welding parts 590 to 980 MPa. It can also be used on 270 to 440 MPa steel. Steels above 980 MPa will require STRSW where applicable or MIG brazing where STRSW can’t reach.

Even weld-through primer is addressed. Does Honda allow it? Yes and no. Yes for STRSW and no for MAG welding. There is no more just yes and no; we need to look at the manufacturer’s procedures to be sure we’re not compromising vehicle safety. A simple yes or no may be a thing of the past. Even metal prep and procedures are explained thoroughly. This little bulletin (Honda Body Repair News) has a major amount of information.

Teaching the Industry

Honda is teaching the industry not just what procedures we need to follow but why we need to follow their procedures. Other car manufacturers seem to be following suit. Where to section and why not are being addressed by the industry. It does no good to say you can’t section there without some explanation. To make good decisions on repairs, we need facts, background and training. I commend Honda on this bulletin for explaining why we need to follow guidelines, not just presenting a picture and saying, “Do this.”