Brand-new vehicles are delivered smooth, sleek and flawless to consumers, and that’s how they want them to look throughout the vehicles’ lifetime.

Brand-new vehicles are delivered smooth, sleek and flawless to consumers, and that’s how they want them to look throughout the vehicles’ lifetime.

But let’s face it, life happens. A ding here, a dent there, a scratch or chip in the paint, and people expect miracles from the experts at the body shop to get their vehicles looking brand new again.

Restoring someone’s baby to its original state requires using the best equipment and the latest technology. Body shop owners rely on the latest automotive refinishing spray guns to get the job done quickly and effectively. They want products that will increase the amount of paint deposited on the target and reduce Volatile Organic Compounds (VOCs). By using the latest technology available, spray gun manufacturers are constantly working to provide the safest and most efficient products they can.

Lots of Choices

The options available to painters are numerous, and the choices are improving every day. According to Mark Hebbeler, North American marketing manager for ANEST IWATA USA, Inc., his company produces spray equipment for every application purpose, from industrial electrostatic equipment and flat line automatic equipment to airbrushes. ANEST IWATA’s sister company, Iwata-Medea, supplies airbrushes and small compressors used by custom painters. Hebbeler says its latest product, the LPH400 LVX eXtreme Base-coat Gun, improves basecoat application productivity.

Motor Guard Corporation imports and distributes the Optima Euro 900 spray gun. President David Barleen claims that precise manufacturing with computer-controlled machining centers ensures that every gun delivers the same precision output for optimum fluid transfer. He also states that, through fine atomization, reduced overspray, high transfer efficiency and low air consumption, the Euro 900 achieves excellent finish quality.

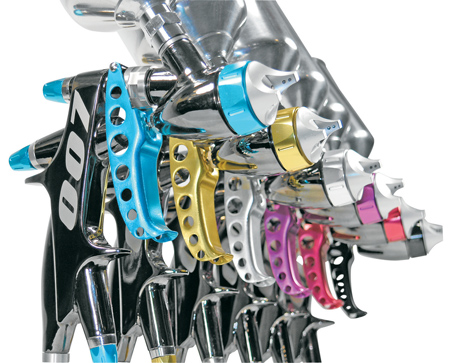

Another spray gun out there is the second version of the 007 Extreme Performance by Dura-Block. “It’s the only gun on the market that has a lifetime warranty. That’s how confident we are in it,” says Cliff Turnbull, vice president of imports. He also claims that the 007s are the only guns where you can interchange the head and still keep the fluid in the head.

“The 007 spray gun allows you to go from primer to topcoat or car to car and not have to stop to clean out the gun, change needles or take the gun apart because their fluid passages are separated from their air passages,” says Turnbull.

The Razor HVLP came about from Graco’s desire to bring a better gun to the marketplace after it purchased Sharpe, says Penny Hanson, product marketing manager. Sharpe believes its family of Razor guns provides superior atomization, spray patterns and material flow. In its view, the new single gun platform makes the refinish process easier because a painter only has to use one gun from clearcoat to primer material rather than switch between guns to complete various jobs. In theory, this means less time spent learning and maintaining multiple guns, and more productive time spent in the spraybooth.

Sharpe introduced the next-generation Finex at last year’s International Autobody Congress & Exposition (NACE).

“What makes this Finex family of guns unique is that they’re the only guns in this import class that have high-end features,” says Hanson. Also, they have interchangeable aluminum cups and are easily repairable and lightweight. There’s also a 3M PPS Adaptor for separate purchase with the guns. According to Graco, the new V.I.P. Finex guns feature 29 percent fewer parts, precision plastic lids, repair kits, the lowest trigger pull among guns in their class and unmatched spray pattern size and quality.

Waterborne Ware

Automotive refinishing spray gun manufacturers are improving their guns to work more effectively with waterborne paints.

“It’s all about equipment for waterborne paints,” says Steve Treutel, national industry relations and training manger for SATA. From exterior chrome finish, which makes cleanup easier, to special coatings in the fluid passage that eliminate any possibility of corrosion, the new SATAjet 3000 HVLP and RP (Reduced Pressure) have been designed for waterborne paints, Treutel says.

According to Hanson, the standard Sharpe line of guns can shoot waterborne paints, but painters probably won’t get the best end-product. To solve the problem, Sharpe recently launched a new product line for waterborne paint products, the Razor Waterborne HVLP.

Motor Guard’s Barleen says his company has not had to design a new spray gun to accommodate waterborne paint.

“So far, the Euro 900 is totally compatible with all the waterbornes out there. We’ve been able to shoot any of the paint manufacturers’ product offerings.”

Dura-Block’s Turnbull says his company’s gun is also waterborne-ready. “The 007 Version 2 is completely set up and designed to be used with the new waterborne paints. They increased the atomization for that purpose,” he says. “All of the internal parts have been switched over to the stainless steel and aluminum parts, so there are no parts that will rust.”

According to ANEST IWATA’s Hebbeler, all of its guns have stainless steel fluid passages needed for waterborne use.

“Our spray equipment has been waterborne-ready for the last 15 years,” he says. “We also supply a complete drying stand outfitted with our Aquadry blowers that have multiple adjustments and provide a 6:1 ratio.”

Going Green

A major goal of most spray gun manufacturers is to minimize VOCs and reduce energy consumption.

Dura-Block has revised the newest 007 to be much more efficient than the original version. It has about 30 percent more atomization and less overspray than the original version. According to Turnbull, when using the 007, there’s no reason to exceed anything above 30 psi.

As far as Sharpe goes, it has created the Compliant Gun within the Razor family of guns. “The Compliant Gun was created for specific states and counties where the HVLP won’t cut it and they need something more restrictive,” says Hanson. The gun is awaiting approval right now from the Southern California Air Quality Management District, where the first product changes were mandated July 1.

Barleen states that Motor Guard’s Euro 900 creates low operating air consumption with its air atomization technology. It operates at less than 8 cfm when operated in AQMD-compliant settings.

“This puts less demand on the shop’s air compressor, saving energy,” he says. “Also, the Euro 900 minimizes airborne VOCs with its same fine atomization technology, increasing the paint material transfer to the panel, thus reducing ‘overspray’ in the shop.”

Barleen adds that the M-C 100 Final Filter removes VOCs from the compressed air supply with its activated carbon filter element.

ANEST IWATA’s Hebbeler says that its LV technology reduces the amount of air pressure needed to properly atomize paint, which reduces the amount of VOCs sent into the atmosphere as overspray. “Our focus will remain on how to reduce VOCs and paint waste,” he says.

Treutel says SATA has three-stage air filtration with charcoal to eliminate oil vapors, which can cause small pinhole contamination with waterborne paints.

“We actually are now spraying with breathing air quality for cleaner paint jobs to reduce redos,” he says. “This filtration then allows the painter to use it for breathing at the same time. We also have three different drying stands with dry-jets for blow drying of waterborne paints.” Treutel claims that the SATA dry-jets use the least amount of air in the industry.

The Next Generation

Although most manufacturers are satisfied for the time being with the functionality of their spray guns, all of them are looking at improvements.

Motor Guard says it’s working on new air treatment tools. “Waterborne finishes require air that’s free of oil vapor,” says Barleen. “What we have had to do is develop a special filter with activated carbon to remove the oil vapors.”

To that end, Motor Guard has just introduced the M-C100 Activated Carbon Filter. The company says that the addition of the M-C100, set up as the final stage in an existing air management system, ensures defect-free finishing with waterborne materials.

“It’s the answer for a final spraybooth filter. It will allow waterbornes to work better,” says Barleen.

Turnbull says that Dura-Block is focusing on ways to make its guns more efficient.

“We have technology we’re work- ing on for better atomization that we’re still in the process of patenting,” he says. “We consider the 007 the do-it-all gun in regard to the technology and efficiency it brings to the body shop. It will do more than any other gun can do and saves the body shop time and paint.”

“We’re always working on new products and new ideas. I don’t think we’re ever going to stop,” Turnbull adds. In fact, he believes every spray gun manufacturer is working daily to make a better atomizing spray gun with less air requirements. Most, he says, are going to remove the aluminum process and migrate toward a composite housing. Finally, he says that everyone is also working toward offering products that are more environmentally friendly.

With the environment on its mind, Dura-Block is working on another version of the 007 that will have features which Turnbull says will allow them to label it the “environmentally friendly” gun. Also, he says people will be pleasantly surprised at its price.

Hebbeler says that ANEST-IWATA’s design team is also working hard at getting a handle on the look and feel of future spray equipment. “We can say with absolute certainty that our guns will be lighter and more efficient than our current offerings.”

Lisa Fink, marketing communications manager for DeVilbiss Automotive Refinishing, predicts that future spray gun technology will feature free airflow and high-performance air caps that atomize high solids materials better. These guns will provide more pattern coverage while consuming less air. All guns will be waterborne compatible.

A Big Investment

As technology becomes more complex, shops must make big investments to stay current.

“The investment to keep up with the technology is very expensive,” Barleen says. “It’s getting harder to succeed as a body shop in today’s environment. The smaller shops are going out of business. Every time another level of complexity is introduced into the body shop, it adds another expense.”

Barleen added that he sees the industry moving toward the large shop that utilizes the latest technology available to efficiently complete the repair.

“This includes the latest efficient paint spray guns utilizing the new waterborne materials to not only reduce VOCs but also provide an exceptional finish in the minimum labor time,” he says.

SATA’s Treutel also sees many changes in spray gun technology on the horizon. “As paint companies continue to change their products, you’re going to see different nozzle generations, increased transfer efficiency and probably even less air. You need to have guns that do the atomization, but then also have the transfer efficiency so that the shops are still profitable.”

Rebecca Roach is a Boulder, Co.-based freelance writer who specializes in automotive and business reporting. She can be reached at [email protected].