TIME TO GET PREPARED!

As Toyota moves forward with the production of Electric Vehicles (EVs), Hydrogen Fuel Cell Vehicles (FCVs), and Hybrid Vehicles (HVs), the question is: Is your collision repair facility prepared for the challenges that these vehicles present?

LIGHTER, MORE SOPHISTICATED VEHICLES

To make vehicles more efficient, Toyota is making vehicles lighter and more sophisticated:

- Reduced weight means the vehicle requires less power to get moving.

- More sophistication means implementing technology that makes the powertrain more efficient.

What does that mean for your collision repair facility?

It means that estimating, diagnosing, and repairing an EV, FCV or HV damaged in a collision presents new challenges that shops have never seen, including:

- Disarming the high voltage systems

- Additional refinishing time

Toyota’s Technical Information System (TIS) techinfo.toyota.com provides you with assets that will help you get up-to-speed on these high-tech vehicles. When a Toyota EV, FCV or HV comes into your shop for collision repairs, Toyota has a bulletin that outlines how to protect yourself during repairs and provides precautions that need to be taken prior to the inspection and service of the high-voltage circuit.

BEST PRACTICES

When an EV, FCV or HV has been in a collision, there’s a chance that the battery and its contents have been compromised. The major dangers of damaged batteries and wiring are electrocution and combustion. As a precaution, all high-voltage batteries should be treated as though they are unstable.

Here are some procedures technicians need to be aware of when working on an EV, FCV or HV:

- Wait at least 10 minutes to discharge the high-voltage capacitor inside the inverter.

- If the battery has been damaged or punctured, the vehicle should be isolated in a place at least 50 feet away from other flammable or combustible materials (due to some batteries being extremely difficult to extinguish once they are on fire).

- Place any object that could start the engine or hybrid system, including key fobs, away from the vehicle. They should be locked in a container and moved out of range from the vehicle.

- Once a high-voltage battery is disabled and discharged, the vehicle should never be rolled on its wheels, as this can generate voltage to the battery system.

- High-voltage personal protection equipment may be necessary, including gloves (rubber and leather), boots, face shield, and safety glasses.

- Check insulated gloves to be sure they are free of cracks, tears, and other types of damage before starting your work.

- When servicing the vehicle, do not carry any metal objects—like mechanical pencils or rulers — that can be dropped accidentally and cause a short circuit.

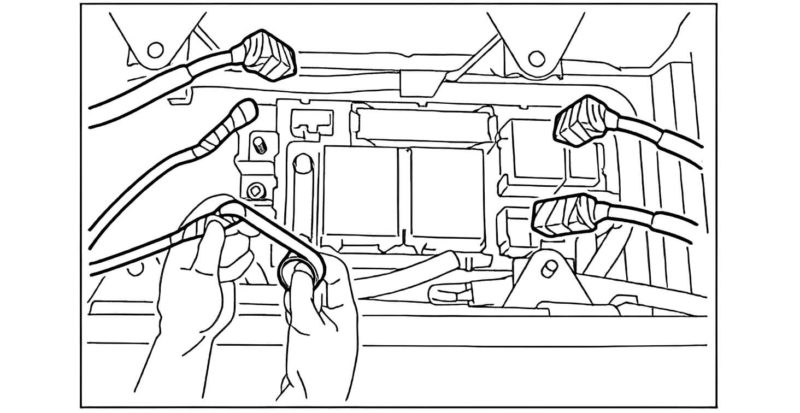

- Before touching a bare high-voltage terminal, wear insulated gloves and use a tester to make sure that the terminal voltage is 0 V.

- After disconnecting or exposing a high-voltage connector or terminal, insulate it immediately using insulating tape.

- Bolts and nuts used for high-voltage terminals should be tightened to the specified torque — insufficient or excessive torque could cause a failure.

- Use the “CAUTION: HIGH VOLTAGE DO NOT TOUCH” sign to notify others that the high-voltage system is being inspected and/or repaired.

- When welding on an EV, FCV, or HV, follow the same precautions as when welding on a conventional vehicle; as a best practice, disconnect both the 12 V battery and the high-voltage battery service disconnect.

- After servicing a high-voltage system and before reinstalling the service plug grip, check that you haven’t left any parts or tools inside, that the high-voltage terminals are firmly tightened, and that the connectors are correctly connected.

- When working on a high-voltage circuit, use either a tool wrapped with vinyl insulation tape or use an insulated tool.

There are additional guidelines and cautions, so be sure to read the appropriate bulletin before starting repairs.

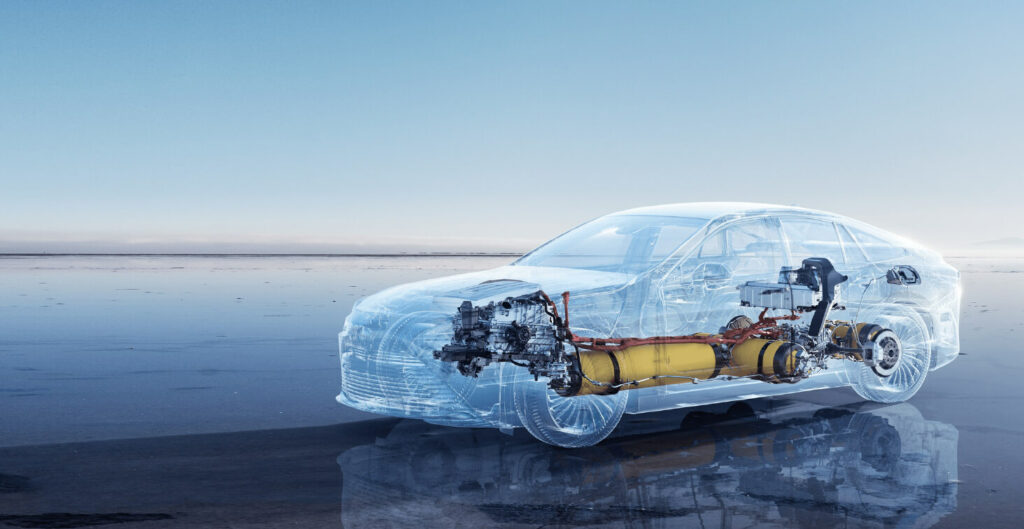

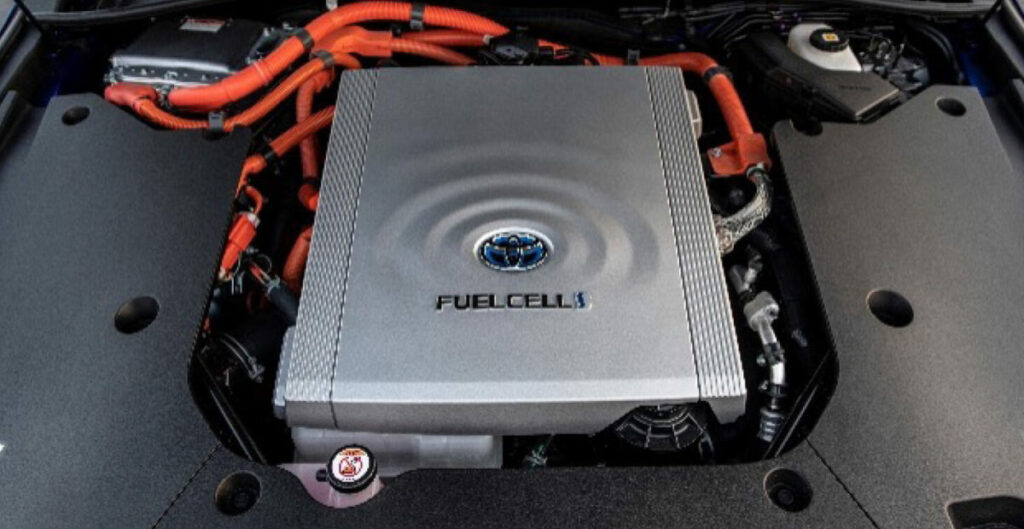

WORKING ON THE MIRAI FUEL CELL VEHICLE

Before starting repairs on a Mirai, an FCV-Qualified Toyota Dealership and Technician must be consulted to assess the damage to the hydrogen fuel system components (i.e., the fuel cell stack, fuel system piping, receptacle, tube joints, sensors, regulator, and tank assemblies) prior to collision repairs. Please contact the Toyota Customer Experience Center for FCV-Qualified Dealers: 800 331-4331.

Many of the precautions for EVs and HVs are the same for the Mirai, but you must remember you are dealing with compressed hydrogen stored in tanks.

Before touching a bare high-voltage terminal, wear insulated gloves and use a tester to make sure that the terminal voltage is 0 V. After disconnecting or exposing a high-voltage connector or terminal, insulate it immediately using insulating tape.

- The tanks on Mirai store hydrogen at high pressures and the hydrogen must be released prior to removing the tanks from the vehicle. Have an FCV-Qualified Toyota Technician assist in the releasing of the hydrogen.

- High-pressure hydrogen pipes have red insulation for identification purposes.

- Toyota genuine fuel cell stack coolant cannot be reused — refill only with new Toyota Genuine FC Stack Coolant Full Service Kit-20L (P/N 08889-80350).

- When cutting and welding, do not allow sparks or hot fragments to contact the hydrogen fuel components. If that occurs, remove the hydrogen tanks before proceeding.

- Do not allow solvents to contact the hydrogen fuel tanks.

SAFETY FIRST

Safety is key. Always be sure to do your research and take the appropriate precautions prior to working on one of these sophisticated vehicles.

ACCESSING THE DISABLE PROCEDURE

Here’s where you can find the Toyota High-Voltage Disable Procedures:

- Go to techinfo.toyota.com

- Enter your username and password

- Click Login

- Click on TIS Tab

- From the dropdown, select the Division, Model, and Year

- Click the Search Button

- Click on the RM Tab

- Click on the blue text

- A new page will open in a popup window

- Click the dropdown menu for Engine/Hybrid System and select Hybrid/Battery Control

- Click the dropdown menu for Service Plug Grip and select Removal

For more of the latest news, product information and best practices from Toyota, visit https://www.toyotapartsandservice.com/collision-pros-magazine.