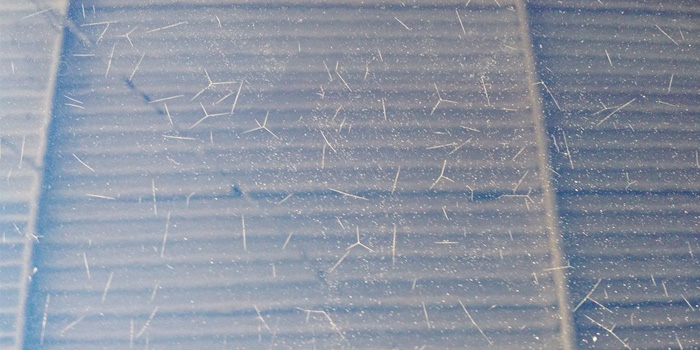

I own a body shop, and we recently received a car with damage on the paint. The best way I can describe it is that it looks like crow’s feet. How do I fix this?

I own a body shop, and we recently received a car with damage on the paint. The best way I can describe it is that it looks like crow’s feet. How do I fix this?

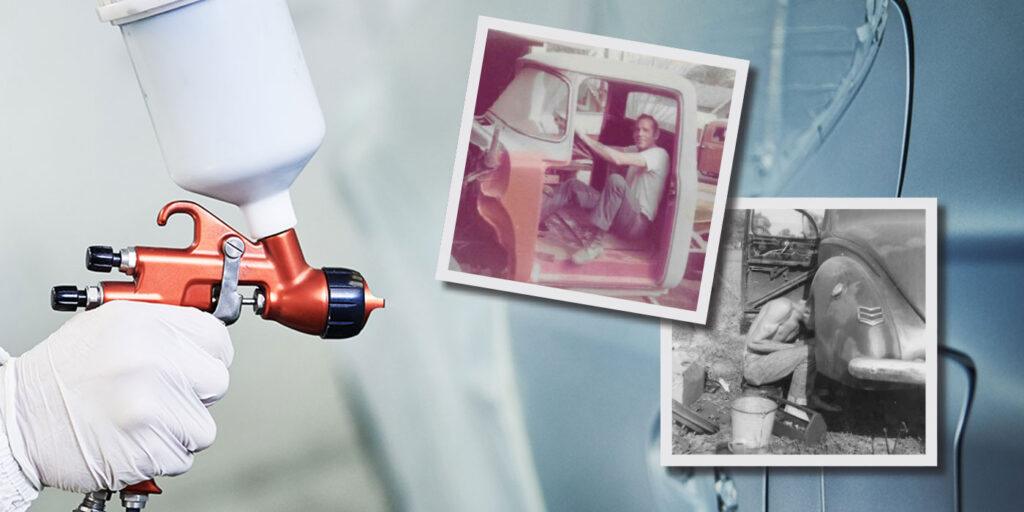

The paint problem we see here is a condition known as “checking.” It is typically caused by excessive film build.

A common, modern-day OEM paint job will be in the neighborhood of 6 mils thick. That’s everything – e-coat, sealer, color and clear. We can safely put another paint job over it, particularly if we activate the basecoat, presuming we’re using modern 2K products, perhaps two more depending on the nature of the repair. Most paint manufacturers want us to draw the line in the 10- to 12-mil range and recommend stripping these excessive coats to the original OEM undercoat prior to refinishing once the paint film has reached this threshold. If the panel(s) are stripped to the substrate (steel or aluminum), then additional refinish steps must be employed to ensure proper corrosion protection.

There are mil gauges available, from simple magnetic ones that work only on steel for less than $100 to other expensive units for $500-plus that utilize a technology that measures the density of the film rather than the interference, making them suitable for aluminum.

Another similar-looking paint failure known as ‘crazing’ is less common as it is a failure of acrylic lacquer, which we see much less of these days. Crazing is a result of excessive stresses, which may or may not be set up in the film during drying, and then are suddenly released. This condition can be present in paint films which are well within acceptable mil gauge ranges.

The only cure for either of these paint failures is to strip the topcoats prior to refinishing. If, as in crazing, the offending layer of paint was at the OEM level and had subsequently been refinished, then everything down to the OEM undercoat needs to be stripped.

More information: