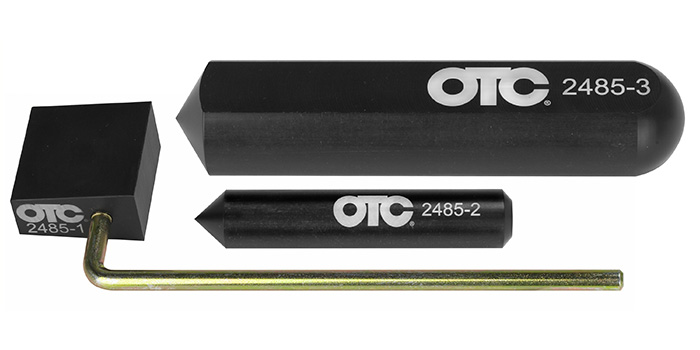

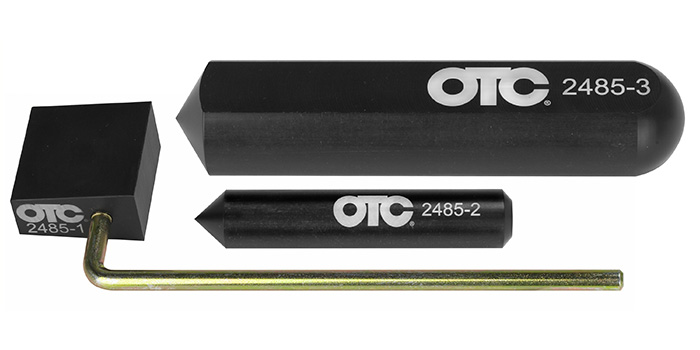

OTC has released a set of synthetic body tools designed especially for use on aluminum panels. In order to reduce weight and achieve higher fuel economy, many high-volume vehicles are using aluminum in body components. This creates a potential challenge and opportunity for collision repair shops to be prepared with the necessary tools and equipment for aluminum panel removal and replacement. Special hand tools made from synthetic material have great shock absorption qualities, greatly reducing the risk of marring, scratching or gouging panels. A variety of drill bits, weld breakers, wedges, trim tools, finishing tools and general shaping/bumping tools will address most aluminum repairs. The tools are designed to break spot welds, remove trim pieces and reshape aluminum panels after a damaging event. Featuring 19 synthetic tools that are warranted for life and three super-hardened and tempered spot weld drill bits, the OTC line guarantees body shops can have a dedicated set of tools for aluminum panel removal and replacement. Lightweight aluminum has different principles of memory and cannot be treated like steel. These synthetic tools are an excellent alternative to steel tools, which can scratch, gouge and over-stretch aluminum. For smaller dents and dings, the synthetic tools can often perform a repair without the need to paint, saving time and money in a collision repair facility. First to market with Cornwell Tools, the OTC line is available now through Cornwell distribution. In August, the tools will be available through OTC’s traditional distribution methods. For more information, visit www.OTCTools.com.

OTC has released a set of synthetic body tools designed especially for use on aluminum panels. In order to reduce weight and achieve higher fuel economy, many high-volume vehicles are using aluminum in body components. This creates a potential challenge and opportunity for collision repair shops to be prepared with the necessary tools and equipment for aluminum panel removal and replacement. Special hand tools made from synthetic material have great shock absorption qualities, greatly reducing the risk of marring, scratching or gouging panels. A variety of drill bits, weld breakers, wedges, trim tools, finishing tools and general shaping/bumping tools will address most aluminum repairs. The tools are designed to break spot welds, remove trim pieces and reshape aluminum panels after a damaging event. Featuring 19 synthetic tools that are warranted for life and three super-hardened and tempered spot weld drill bits, the OTC line guarantees body shops can have a dedicated set of tools for aluminum panel removal and replacement. Lightweight aluminum has different principles of memory and cannot be treated like steel. These synthetic tools are an excellent alternative to steel tools, which can scratch, gouge and over-stretch aluminum. For smaller dents and dings, the synthetic tools can often perform a repair without the need to paint, saving time and money in a collision repair facility. First to market with Cornwell Tools, the OTC line is available now through Cornwell distribution. In August, the tools will be available through OTC’s traditional distribution methods. For more information, visit www.OTCTools.com.