New vehicle features mean that performing a quick toe adjustment could cause more problems.

You have probably seen the results of a “toe and go” alignment, a service that ignores camber, caster and diagnostic angles like SAI and included angle.

The result might be a straight steering wheel, but the driver knows something is not right because it does not feel right going around turns. On some vehicles, you might be able to get away with a “toe and go” alignment. But with stability control and advanced safety features, the sensors might catch your shortcut.

Scanner for the Chassis

Should a shop charge more for ADAS alignments? Yes. Your alignment bay should be treated as a colossal scan tool that can pull the angles from the vehicle so they can be used for diagnostics of the chassis and suspension. Adjustments performed like camber and toe are just like calibrating a sensor, but the process is, of course, completely mechanical.

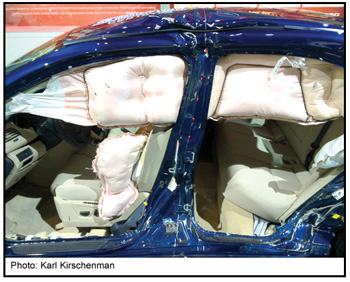

The other factor changing the alignment process today is the growing population of vehicles with stability control systems. Some of these require extra steps after the angles are adjusted to calibrate the steering angle sensor.

The Basics

No matter how advanced the ADAS or autonomous driving system can be, the pre-alignment inspection with a tire pressure gauge, tape measure and your eyeballs becomes even more important.

Always check tire inflation pressures because a low tire will pull. It’s also important to note tire sizes. A car will pull toward the side with the smallest tires or the side with wider tires. A wide tire offers higher rolling resistance than a narrower tire. Wide tires also tend to be more sensitive to road crown steer than narrower ones.

Measuring ride height becomes even more critical with more advanced vehicles. With changes in the ride height for vehicles with cameras and radar sensors, ride height is even more critical. If the ride height changes, so does the angle of the camera in relation to the road.

Inspecting the entire suspension is critical because sometimes the alignment angle sitting on the alignment rack is just a static snapshot. If bushings are worn out, the alignment angles can change.

When angles change and the vehicle starts to pull, some electric power steering systems will attempt to add assist. It does this to compensate for normal pulls like road crown.

Test Drive

With systems like lane departure and automatic cruise control that can steer the vehicle, the post-alignment test drive takes on a whole new meaning. Many systems, like lane departure, do not activate until a specific speed is reached and the road markings are present. It is critical to look at the service information to find procedures and the activation criteria. If you fail to complete this step, the customer might be back complaining that you broke their vehicle.

Andrew Markel is an ASE-certified technician and former service writer, and he brings this practical knowledge to the Babcox Media team as director of content.