Over the last couple of years, I’ve come to the realization that there is so much you have to learn to succeed in the automotive repair world. Issues that just a few short years ago were straightforward have changed dramatically. Changes in business environments and vehicle manufacturing have forced owners to have a degree of knowledge in business, marketing, financing, accounting, HR and repairing vehicles correctly. Expanding your business takes much more research and consideration than before. The expense of equipment and finding employees — or, better said, “qualified” employees — has been a challenge recently. As to the business end of the expansion, that’s up to you and your stakeholders.

The electronics repair industry will continue to grow as more electronic controls and features increase every day. It has grown to where we must designate certain technicians with ASE certifications to the specialized repairs that must be completed on these vehicles. A few recent studies have shown that many repair facilities are still not doing calibrations that are called out in repair guidelines to validate that the systems are operating correctly. Researching and following the service information has proven to still be an obstacle to many in the industry. This is exacerbated by the differences in opinion in the industry between the words “recommended” and “required” — and we’re still trying to define “collision.” Even with the confusion, we know the electronic repair industry will grow.

The Challenge

The challenge any company will face in expanding into electronics repair is that it will need to be able to work on multiple brands, all of which have different variables. The electronics repair industry is changing every day, and those changes being developed and improved by vehicle manufacturers along with new security systems designed to protect those electronics present challenges and costs to all levels of the repair industry. The demand that certified shops provide documentation that the original equipment (OE) software was used to program, calibrate and validate that all repairs were done is also a consideration if you’re going to offer scanning and calibration for collision repair shops.

Let’s add to this that manufacturers who are developing scan tools to service all these vehicles are changing their software and tools to access the vehicles too. With a focus on delivering a tool to work on multiple lines of vehicles, a shop has to look at what their needs are and who will not only provide tools for past and current years and models but who will be able to provide tools for future vehicles. All of this represents time-consuming research, not to mention the cost of the equipment and software. This is just part of the daily grind of starting and maintaining a company that services electronics repairs.

One assumption in the industry is that you just plug into a vehicle and press clear — which brings up the subject of the additional time involved in educating your customers as to what’s actually needed and required to complete the vehicle repairs. There are still a lot of people who feel if there is no light on the dash, let it roll. Other variables in today’s market are supply shortages and labor shortages, which affect every aspect of the automotive repair industry.

What Level?

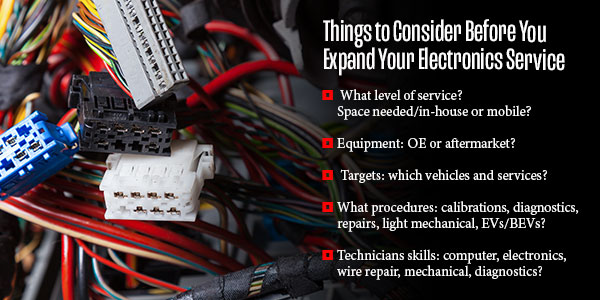

The electronics repair part of the auto body repair world is requiring all repair professionals to learn more about the different types of features being offered in vehicles and the variety of procedures required to repair the vehicle. With this thought in mind, you’ll need to decide what level of service you want to provide to customers, who in this case will be the repair shops.

Doing calibrations is what I consider the entry level of electronics repair. However, do not be fooled by the “entry level” term, as there is a lot to learn and it is expensive to get into the game. Even calibrations will have complexities you’ll need to think through as an owner or manager. An example would be that, on some Nissan and Hyundai/Kia vehicles, an alignment procedure must be done to verify the adaptive cruise control (ACC) or blind spot monitoring (BSM) radar is correctly positioned on the vehicle. This must be done prior to the installation of the bumper cover. Many shops do not complete the alignment procedure and then perform the ACC or BSM calibration, which calls for alignment of the radar. Are your employees going to remove the bumper cover that the shop just repaired and painted? Let’s forget that the service information said to verify alignment and just say it failed calibration. Now, to diagnose the issue, the bumper cover needs to come off. Are your technicians going to remove the bumper cover?

This scenario alone raises so many questions as to what level of service you’ll be providing. If you’re expanding to build a static station where you’re having vehicles delivered to your facility or providing porter services, there will have to be a different resolution to the bumper scenario mentioned above than bringing a mobile service to the shop where the vehicle is located. There are advantages to both; maybe a combination works best. You’ll need to decide what you need and have employees to fulfill those roles. What level of service are you looking to offer, and what will it take to get there? Some start out just doing calibrations and expand as they go. Or, some companies add skills to their technicians as customers’ requests and repairs dictate.

I look at industry leaders who have taken on the challenges and are growing their businesses, and I see the effort it takes to not only maintain but keep up with the industry. People like Jacques Navant of Don’s Mobile Glass, Rick Zirbes of Smart Express and Chris Gutierrez of Protech dedicate a great deal of time to researching tools and educating customers on what is needed to repair vehicle electronics correctly. They’ve also learned that it’s not just about calibrations; wire repair, programming, replacing or diagnosing wiring harness damage, airbags and seatbelts are just the tip of the iceberg as to what a shop is looking for service-wise.

Tools

To get started, you need to realize that no one tool is going to fit for all I just mentioned. To meet your customers’ needs or to sell your company, you’ll need to be flexible and attentive to the market and see new things being introduced. Research will never end, and you can’t afford to be complacent.

As to the OE tools — such as the OE software, be it a scan tool or computer-based, and VCI connectors for the vehicles — research brands, what year of brands you’ll be servicing and your customers’ certifications. Purchasing the right equipment as well as costs of subscriptions and fees for different procedures, like downloads for programming, need to be considered — this is a very big marketing point that some miss. Having the same software as the OE is a great selling point, especially when it comes to new vehicles rolling off the line. This also has advantages when vehicle manufacturers use certain types of gateway modules and security to prevent access to sensitive electronics.

I’m a big supporter of OE procedures and equipment, but I also understand that aftermarket equipment has a place too as long as it follows OE processes. Alternative or aftermarket tools are a mainstay at any shop, as they offer access to multiple lines of vehicles. Snap-On, Bosch and AUTEL are just a few companies that are able to offer additional targets and other equipment to complete a plethora of calibrations, including AVM mats, night vision targets, blind spot targets and a variety of VCI to access different year vehicles. As with any tool or software, you’ll need to be sure that all technicians are keeping tools and software up to date.

Technicians

This is a subject I’ve been schooled on repeatedly by friends and people who I work with and respect a great deal. I thought I was relatively well-versed in most things in auto repair until I started listening and learning from colleagues who’ve spent years in the electronics game. There is so much more to the electronic repair of vehicles; I thought I knew it all, but I found out I was quite naive. I’m constantly trying to learn and catch up as the industry changes every hour.

The technicians who are successful in the collision repair industry have a great deal of problem-solving skills that are required for the tasks your company will be performing. Many technicians who have worked as mechanics have learned and developed these skills, as working with newer engines and drivetrains along with suspension components involves a great deal of diagnostics. If you’re just doing calibrations and are thinking diagnostics and problem-solving will not be needed, there are many who will disagree with you. Calibrations fail for many reasons after repairs are completed. Knowing the cause will be a test of your value to a customer. Your customers (repair shops) want someone to not only calibrate but to find the issues still in the vehicle. A “one-stop shop” is the term I hear constantly. A shop wants someone to calibrate, diagnose any issues and fix the issue so the car will still be delivered on time. Going from company to company or to a dealer when failures occur is not always a palatable choice.

Having technicians with diagnostic skills is part of what you need; the ability to research and read SI and wiring diagrams, use a tool such as a digital volt Ohm meter (DVOM) and understand real-time data is another part. We’ve all seen a shop that has a problem with a vehicle struggle to find the cause, only to send the vehicle to the dealer who fixes the problem quick and easy. When you have experience with that vehicle as well as a huge network of people who’ve had similar issues and have the resolution at their fingertips, it seems easy. The point is that technicians in the field need to know all vehicles, not just one. They need to be able to research the issue and find a resolution for the shop quickly. The research involved in diagnostics is often overlooked. Even the time to research a procedure in the service information is overlooked, as people think you just push a button and everything will magically work.

An example is a failed calibration producing an error code on a vehicle. How do you diagnose the cause? Through service information on the code, wire diagrams to see if there is a possibility that a wire is cracked or seeing if a module needs to be reset. Are the mounting brackets bent? Diagnostics will need to be completed to fix the vehicle. What if there is a wiring harness issue? Will you be removing the dashboard for wire repairs or electronics? What about wire connectors? Will your company be replacing or re-pinning any connectors?

Research

You’ll need to research how much space you’ll need to complete the needed procedures. Surround-view systems and mats require a great deal of space and also need to be away from the strong glare of lights. You’ll need a level floor, or the shop you’re doing mobile work for will need the space or level floor in addition to correct lighting. You will also have to figure out what tools (scan tools, software, VCI, etc.) you’ll need for the customer base you’ll be serving.

Another aspect of research is the time to look up the procedures. Accessing websites and adding these procedures to the estimate takes time and effort. This step is not to be taken lightly, as it is essential to be sure all billing is correct. The current litigious world in which we live in forces us to be sure we’re documenting everything we do for our customers.

Summary

All of the things I’ve mentioned in this article are basic entry-level considerations for anyone looking to expand his or her business. There is so much more we’re all learning, as there is no book to guide you through it. It’s a pioneering part of the collision repair industry with humble beginnings many years ago in the mechanical repair segment. With the expansion and growth into auto body repair, there is much we can learn from the auto mechanical side of the industry. Talk with your customers to learn their needs and research your options. Once you have your goals in place, enjoy the roller coaster — it will be an interesting ride as more developments unfold.