Certification should be a lifelong objective for auto technicians and body shops, says Steve Leal, President & CEO, Fix Network World

Over the past five years, I have been quite vocal on several global forums and social media campaigns about the need for body shops to be certified. This is a hot topic that will always remain close to my heart and there are multiple reasons why I support it.

Few can dispute the fact the automotive industry has grown significantly, especially in the past two decades – both in terms of technology and comfort. It’s not just adding a few gadgets here and there, but a complete overhaul of the vehicle-making process. The advent of the Internet and breakthroughs in manufacturing materials means smarter, safer, faster and more environment friendly vehicles.

With rapid advancements in vehicle technology, driving assistance options and new lightweight materials, just having the right equipment and knowledgeable technicians is no longer an option. If you look up the repair procedures of most makes and models, the processes and requirements change from one year to the next due to new equipment complexities or raw materials used in the construction of different components of the structure of the vehicle.

This is where certification assumes greater importance. No longer can body shops remain complacent enough to operate within their traditional comfort zones and repair vehicles as they usually did. It has now become a matter of shaping up or shipping out.

For starters, certification is a set of processes that determines that a technician and/or shop has the desired knowledge, equipment and training to repair vehicles safely and to OEM standards. A certification for a technician and shop in such disciplines is an important assurance to customers and insurances that the shop and technician have met the desired operational guidelines set by local authorities.

Shop certification demonstrates to customers and insurance partners that the team has been trained to manage the most complex mechanical and collision repair requirements and that the shop has the latest equipment to ensure all repairs and services completed on vehicles are to manufacturer specifications.

For shops to be certified, they need to undergo a test of their repair processes and equipment and an independent audit of their facilities to meet the industry’s stringent standards. Many shops around the world have started to invest in quality equipment that improves turnaround time and assures quality control in all processes. These are shops with an eye on the future.

After spending over 20 years in the industry and leading one of the largest automotive aftermarket franchise networks in the world, I will continue to be a lifelong advocate of training and certification for our industry. Towards this end, we are working closely with not-for-profit independent industry bodies in most markets to develop guidelines for certification of shops and technicians.

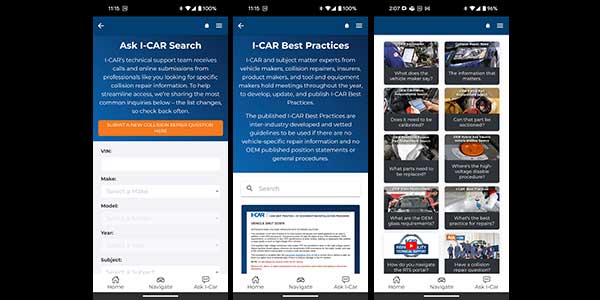

Different countries have different requirements for certification of shops, and I keep underlining to our global network of franchises how certification can help them to elevate their game. Such efforts have yielded positive fruit and I am already seeing greater acceptance among our franchisees to have their teams certified by industry bodies such as I-CAR.

For technicians, continuous learning should be a lifelong process. We need people with an open mind to agree that the repair process will evolve from year to year. Regular training and refresher courses for skilled technicians in the most advanced collision repair technologies prepare them to be better prepared for the future.

As technology evolves, electronic components become more sophisticated and alloys used in the construction of cars become more complex, technicians can no longer rely on past experiences only. They need to read every OEM technical data sheet prior to any structural repair to ensure they meet OEM recommendations and standards for a particular vehicle.

There can, however, be certain stumbling blocks that prevent shops from adopting certification and training as part of their operations. Many shops might be hesitant to pursue this since they wonder if the returns will be worth the investments they have made on the equipment and for the training of their staff.

But for now, the benefits far outweigh the disadvantages and the investment in both time and money will certainly pay off in the longer run. In the next few years, I anticipate that there will be a huge demand not only for certified shops but also for talented technicians who can repair vehicles safely and to top quality standards.

Steve Leal is the President & CEO of Fix Network World, the leading global automotive aftermarket services network which includes ProColor Collision. The family of brands spans over 2,000 points of service internationally.

This article was sponsored by ProColor Collision. For more information, please visit https://procolor.com/en-us/.