Boasting more lines of software code than a jumbo jet, modern vehicles are more complex than ever. But collision repair – when you boil it down to its essential elements – is a “super simple process,” according to one expert.

Mark Olson, CEO of Vehicle Collision Experts and a veteran of the collision repair industry, described a 10-step process for a proper auto body repair, kicking off a Feb. 16 panel discussion at the Midwest Auto Body Trade Show in Altoona, Iowa.

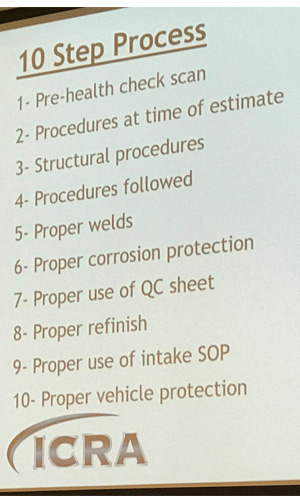

Here’s how Olson breaks down the collision repair process:

- Conduct a pre-repair health-check scan.

- Pull the repair procedures at the time of the estimate.

- Pull the structural repair procedures.

- Follow the repair procedures.

- Perform proper welds.

- Ensure proper corrosion protection.

- Perform quality-control checks.

- Perform a proper refinish.

- Follow your standard operating procedures (SOPs) for vehicle intake.

- Ensure that the vehicle is protected.

“If we did these 10 things on every car, every time, what would our predictable, quality repair outcome be?” Olson asked the audience. “It would be amazing, wouldn’t it? That’s how simple this is.”

As a former shop owner, Olson acknowledged that yes, sometimes things aren’t so simple. But the template at least provides a true north for shops. It also can help shops know when they need to walk away from a repair job.

If there’s a Honda Odyssey in your shop, for example, and you notice that the repair procedures call for a pulse MIG brazer to weld the A pillar – and your shop doesn’t have a pulse MIG brazer – then you need to tell the customer: “I can’t fix your car the right way,” Olson asserted.

“I know that sounds a little bit harsh, but I give you 42 million reasons why” you need to walk away from the job, Olson added, referring to the $42 million verdict in the John Eagle Collision Center lawsuit. “ … The reality is that you might discover that you can’t fix the car, or your technician might not be trained to handle the car, even if you have the equipment.”

While the reality of shop liability – a key reason why the industry is emphasizing the need for proper repairs – was a common theme during the panel discussion, Matthew McDonnell reassured repairers that it’s not all “doom and gloom.”

“I believe that this industry right now is the most absolutely exciting it’s ever been,” said McDonnell, who owns Big Sky Collision Network in Montana. “ … All the information we need is at our fingertips.”

Regarding Step 1, McDonnell said his shops perform pre- and post-repair scans on every car – “no exceptions.”

A few years ago, before he started scanning every vehicle, McDonnell conducted an experiment to see if scanning was necessary. He logged the results of several hundred scans, and found that only a small percentage of the diagnostic trouble codes corresponded to illuminated dash lights.

“There’s only one way to fix the car,” McDonnell said. “We absolutely believe that.”

BodyShop Business contributor and longtime I-CAR instructor Mitch Becker urged shops to make sure that they have the right welding equipment and that their technicians have the right training to perform proper welds. He also noted that I-CAR’s welding requirements now take into consideration the quality of the backside of the weld.

“People bet their lives on our welds,” Becker said. “It’s probably one of the most critical things that we do in our body shops.”

Regarding Step 6 – proper corrosion protection – Olson asked the audience: “How many of you buy at least one can of cavity wax per week per technician who’s doing structural repair in your shop?”

“If you’re not, you’re not buying enough, and you have liability exposure from repair failure,” Olson added.

Look for more coverage from the panel discussion and other Midwest Auto Body Trade Show sessions in the future on bodyshopbusiness.com.