Electronics in vehicles are nothing new in automotive repair. If you’ve been in the repair industry for more than a couple of years, you understand the process of chasing a short, bad ground; failed components; or damaged wires.

Vehicle electronics have increasingly become a main staple of repairs in today’s vehicles. Technology has forever changed the way we all repair vehicles. Even changing or disconnecting the battery has been transformed from the simple procedure it was just a short time ago.

When advanced driver assistance system (ADAS) features started appearing in vehicles, shops did their best to figure out the best way to diagnose, repair and calibrate these new features. Information from vehicle manufacturers was (and, in some cases, still is) a little confusing to many shops, technicians and insurers. Let’s add to this the thought that if you have the software and correct tools to access the vehicle computers and modules, you can fix anything. That would not be true. Experience in diagnostics and/or troubleshooting electronics is not something you can buy. You can have the best tools in the wrong hands and create your own private nightmare when working on vehicles. Experience is about what you’ve learned over time from working with vehicles and applying what you learned to newer and more complex systems. In older vehicles, we hopefully gained that experience necessary and developed some troubleshooting processes to help with newer vehicles.

Time and Experience

Time has been great for the industry to gain experience and new tools to repair vehicles. Time also can work against a shop repairing a vehicle. What happens to these systems over time? Nothing lasts forever, and vehicles are subject to the harshest conditions. We know vehicle manufacturers test and retest systems and validate that the vehicles and all their components will last the expected life of the vehicle. But when we look at how long they can go, testing in labs and certain conditions cannot simulate real life and account for the many variables that the average vehicle is subject to, such as environment and owners failing to clean and/or maintain the vehicle. Another variable to consider is the events from human error that happen to a vehicle during its life, such as minor bumps and bruises that cause unseen damage. The constant fatigue and wear and tear along with those minor bumps and grinds all add to damage that can cause parts or system failures.

In older vehicles, these variables can add up to situations that are difficult for shops, customers and insurance companies to facilitate a repair to a customer’s satisfaction. We’ve all experienced the unrelated prior damage (UPD) scenario in the auto repair industry. Explaining to customers that the UPD will need to be corrected to complete repairs is a difficult situation for everyone. The ADAS components — or, in reality, any component — can add expense that most people may struggle with … and then include the deductible. These situations can cost vehicle owners a pretty penny, to the point where they will not be happy or satisfied when that customer satisfaction index (CSI) questionnaire comes around.

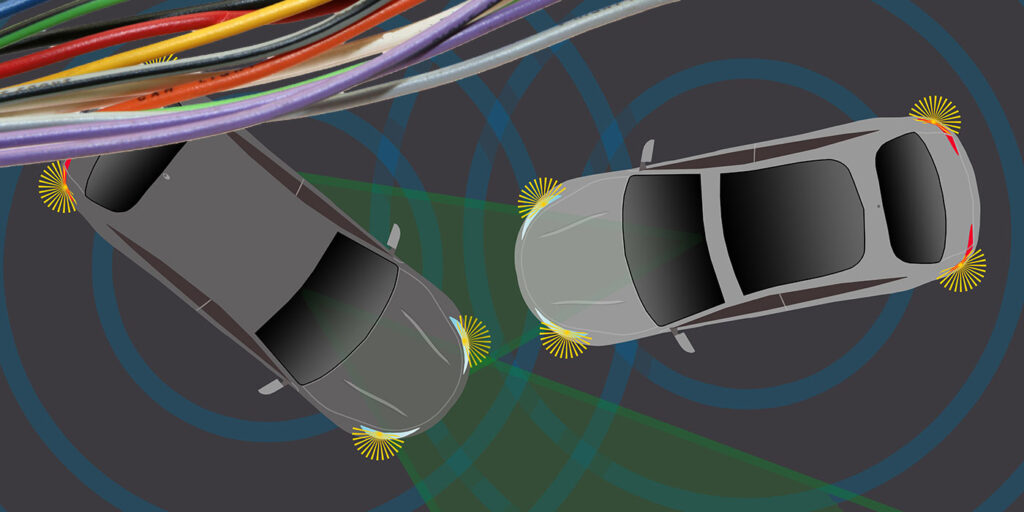

A simple example is damage to a vehicle from 2016 to 2018 that will require removal and installation (R&I) of the bumper equipped with parking sensors. A calibration may be required before delivery. No repairs are completed on the bumper cover except paint. The sensors have suffered damage and have been through some minor bumps and grinds. The problem is that the sensors have been damaged and are no longer communicating to the module correctly, or maybe the mounting bracket behind or attached to the bumper cover for the radar has been bent and the radar is no longer aligned correctly to calibrate.

Another thought to consider is that the vehicle damage did not warrant an alignment, but before calibrating the forward-facing camera, do you know if the vehicle alignment is correct? Is the steering wheel angle sensor calibrated and correct? Experience is teaching all of us as an industry that older systems may require more consideration to complete repairs.

Unrelated Prior Damage

Whether the vehicle is new or old, preparing for UPD in electronics can be difficult. There are some best practices that I’ve have learned from shops and companies that may help to spot the UPD before it becomes an issue later or at the end of the repair:

Customer interview. When the customer is dropping off the vehicle, ask if all the systems are working. Ask the owner to describe what the vehicle does to validate that this person understands how it works. If you get an “I think” or “I’m not sure,” you just identified that the customer may not know or the system is off, either by customer choice (if that’s an option) or by malfunction. Either way, it’s a starting point on whether all systems are operational. An estimator can also be an investigator to protect your shop from unnecessary charges and customer confusion.

Pre-repair scans. Research any diagnostic trouble codes (DTCs) and how they will relate to the repairs. Knowing which systems are experiencing errors will give you the starting point of how you’ll need to proceed to complete the accident-related repairs and what systems must be looked at to complete your repairs and calibrations.

Pre-drive validation. When a vehicle comes in for repairs, validating if the ADAS and other features are operating has become a standard procedure for many shops. I’ve heard so many times, “It worked before I brought it to the shop.” In reality, there are two scenarios here:

- It did not work.

- It did not work and the customer was oblivious to that fact. ADAS systems are still foreign to many drivers, and therefore they are not totally sure how they all work.

Failure to verify that the systems are operational has plagued the auto glass repair industry for years. In some models, the cameras attached to the windows would overheat, and this would not be discovered until after the windshield was replaced and the calibration failed. Upon doing a scan, a camera code was present. Was this from before the glass was replaced or after? As a result of not doing the pre-repair scan and driving the vehicle to validate that the system is operating, the glass companies have shelled out big dollars to replace these cameras.

A Difficult Situation

When a vehicle is towed into your shop, this becomes difficult, and all you’ll have is the pre-repair scan to work with. You can be better prepared, but this will take a different line of thought than most are used to. If the direct damage is to the rear of the vehicle, could that UPD to the front affect any ADAS features — such as blind spot calibrations — to be performed after the direct damage is repaired? Through experience gained over time from working with ADAS and other electronics in vehicles, we’ve learned that ADAS features are intertwined or fused with other systems in the vehicle. A damaged sensor or control module could affect other systems in the vehicle. In many cases, an experienced technician with the right tool and software could access individual modules to complete the repair and/or calibration.

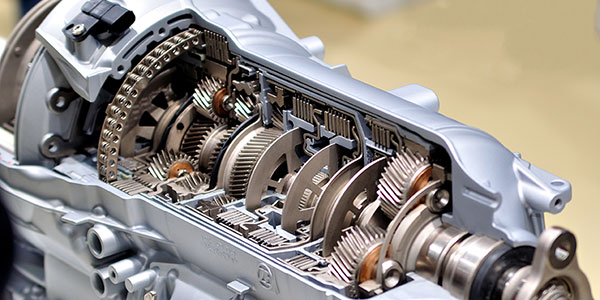

An example would be a DTC in the transmission that is limiting communication on vehicle speed. This DTC is preventing a successful dynamic calibration of the camera mounted on the windshield for lane keeping assist/lane departure warning and automatic emergency braking. The static calibration may be successful, but the vehicle speed is an integral part of the system’s operation during the dynamic calibration.

Technicians have learned that, with some vehicle manufacturers, when a post-repair scan is performed and all codes are cleared, a calibration may be successful as long as the calibration is completed on that key cycle. If the key is turned off and, say, a dynamic test is attempted on a different cycle of that key, the calibration will fail because the transmission DTC code returns. Now, another scan to clear codes must be done — and hopefully the technician reads the instructions on how to do the dynamic test. Otherwise, another company or dealer will complete the calibration and never tell you what was wrong. It seems in this industry that people guard their little tricks and trade secrets. We all know competition is fierce, and dealers — regarding electronic repairs and more — do not want a shop or company to know how to do its job.

Summary

As vehicles age, we’ll start to see more and more how legacy systems, such as automatic braking systems (ABS), power steering and drivetrain component modules, all interact with the new features being added as well as what will need to be done to repair such components as sensors and modules. A damaged or corroded wheel speed sensor or steering wheel angle sensor problem will cause adaptive cruise control or lane keeping assist/lane departure warning to not function correctly. The vehicle alignment can have a major effect on many safety features old and new. The integration of all these electronic components and their interaction will only increase in all vehicles each year. Each manufacturer will have quirks and differences that will be learned with time and experience.

The one thing we’ll all need to remember is that although there are flow charts and schematics we can use as well as written procedures, these do not account for what happens when that vehicle gets crushed in a crash. The electronic control modules, wires and connectors are all messed up. One module not communicating will affect multiple systems.

Technicians who have been working on ADAS components or vehicle electronics have learned many differences and oddities to working with all the old and new electronics. This type of vehicle repair will be different for each vehicle depending on the damage variable of the vehicle. I’m not sure if there is one standard service on a vehicle in today’s world of auto repair. Without researching the damage and types of repairs on the vehicle being serviced, it would be difficult to know what calibrations are needed. Knowing what vehicle manufacturers are recommending/requiring after collisions is a part of the research a good technician does to verify that all repairs are complete. All this plus the vehicle’s age and time on the road and how all systems are affected makes this a very interesting industry, to say the least.