BASIC GUIDELINES AND RESOURCES!

The use of adhesive materials in collision repair is expanding. That’s because vehicles have changed how they are manufactured at the factory and how they are repaired in collision repair facilities. Therefore, adhesives play a vital role in both processes. Just as you need to use the right tool for the job, the same applies to adhesives — you need to know which adhesives are available, but more importantly, which ones are recommended and approved for the repair of Toyota vehicles.

The challenge is when a vehicle has been in an accident. Your collision repair facility must understand where adhesives are used on the vehicle and how to repair the damaged area. There are precise techniques required for each type of adhesive — for example, how thick it should be applied, if it needs to cure if it requires two components, and more.

UNDERSTANDING THE FOUR GROUPS OF ADHESIVES

There are four types of adhesives you may have to work with when repairing a Toyota. They are:

- Epoxy — this is a 2-component product, which consists of a mixing resin and a hardener. When the two are mixed, it creates a chemical reaction which leads to curing to form a strong bond.

- Urethane — these are typically used as a windshield adhesive and can be a 1-component or 2-component compound.

- Acrylics — these are similar to epoxy.

- One-component caulks

The key is to know when to use each adhesive, as some are best when bonding to bare metal, while others are good when you need flexibility.

POSSIBLE ISSUES WHEN USING ADHESIVES

Not all adhesives are created equal — the same can be said for how to handle each adhesive. Each adhesive has specific instructions on how to mix, apply, and cure. Be sure to follow the exact instructions; otherwise, it can lead to customer dissatisfaction.

Here are some basic guidelines to be aware of when it comes to working with adhesives:

- Be aware of how adhesives are stored. Typically, they should be stored at a temperature between 60o – 80o. Too cold or too hot, and that can damage the adhesive. Also, they should not be in direct sunlight — they should be in a protected environment.

- Check the expiration date — adhesives can go bad; using an out-of-date product can compromise the repair.

- Read the instructions, mainly when using 2-component adhesives. Make sure you are using the recommended ratio when preparing an adhesive.

- Be sure to mix thoroughly — again, this is vital with 2-component adhesives as you must mix them properly to be effective.

- Create a sample bead before applying it to a vehicle. It allows you to see if the product performs as expected before applying it to a customer’s vehicle.

- Be aware of the ambient temperature when you are working with adhesives. If the recommended temperature is 70o and your shop is at 90o, curing happens quicker. Therefore, if you know that you are working in a hot environment, consider using a slow-cure product to allow ample time to work with the product before it sets.

- Consider the metals you are bonding. For example, acrylic metal bonding adhesives tend not to work well with zinc or galvanized metal. That is why it is vital to refer to TIS to use the appropriate adhesive recommended by Toyota for the repair you are performing.

- Panel preparation — in many instances, you will need to grind off the e-coat before applying adhesives. So be sure the surface is prepared correctly, clean, and ready.

Adhesives play a vital role in the repair of today’s modern vehicles. Always refer to TIS to ensure you are using the right products, in the right situation to create an effective repair.

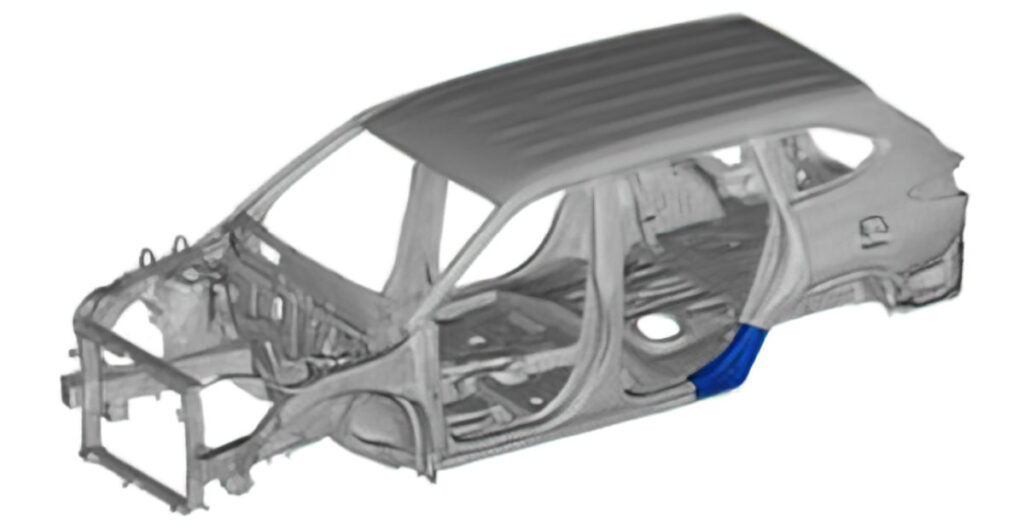

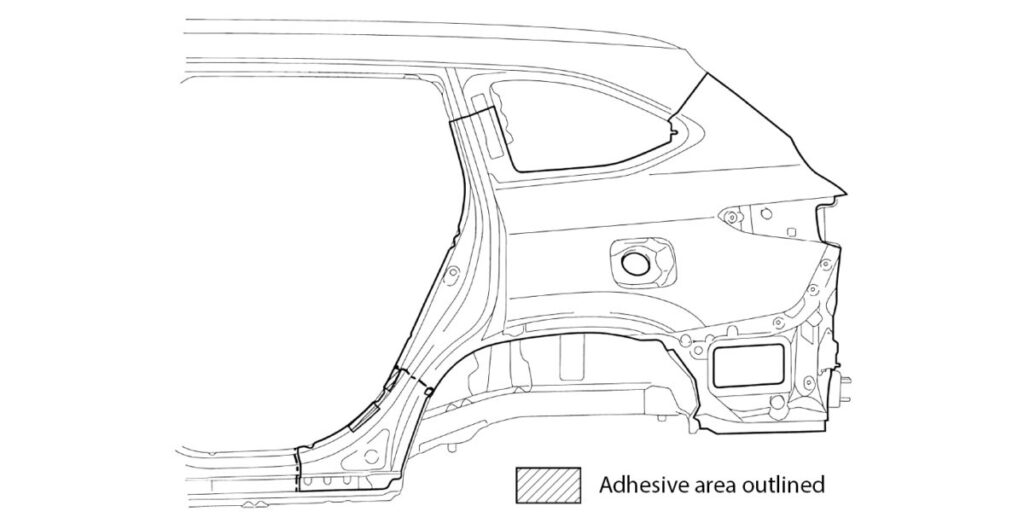

QUARTER PANEL REPLACEMENT USING ADHESIVE

Highlander HV — Model Year: 2021

- Cut the wheel arch portion.

- Heat the quarter panel adhesive area and remove the quarter panel.

- Using an industrial heater gun or gas burner, heat the quarter panel to 110 to 140°C. Make sure the quarter panel does not warp

- Clean off any adhesive that remains on the vehicle.

- Using an industrial heater gun or gas burner, heat the adhesive to 110 to 140°C.

- Using a scraper, scrape away the adhesive.

- If adhesive remains, the strength of any subsequently applied adhesive will be weak.

- If adhesive remains, the strength of any subsequently applied adhesive will be weak.

- Using a disc sander or belt sander, scuff and sand any adhesive that remains on the vehicle.

- Scuff at a width of approximately 10 mm (0.39 in.) over the previous adhesive coating.

- Apply adhesive to the exposed metal areas on the vehicle. Using a spatula, spread the adhesive evenly. Apply adhesive to the vehicle again.

- Apply the Adhesive to the vehicle again.

- Using #60-120 grit sandpaper, scuff the adhesive application area on the new quarter panel.

- Apply adhesive to the new quarter panel. Using a spatula, spread the adhesive evenly.

- Using a vise grip or the palms of your hands, press the quarter panel so that the thickness of the adhesive is even.

- Complete installation of the new quarter panel.

BEST PRACTICES

When you encounter a collision repair, the first thing to do is to go to Toyota’s Technical Information System, TIS. To make it easier for you to know which products to use and the proper techniques, that information is detailed in TIS techinfo.toyota.com.

Here’s where you can find what adhesives you need when repairing a Toyota specific vehicle:

- From the dropdown, select the Division, Model, and Year

- Look in the Collision Repair folder

- Topics you may encounter include:

- Adhesive and Weld Bonding at Specific Locations

- Method not Approved

- Substituting Adhesive for Welds

Always refer to the Repair Manual for Collision Damage for the specific model for locations of any panel bonding adhesive use in body panels. The topics can vary from model to model, year to year. That’s why it is so essential to check TIS and read all the applicable service bulletins when a vehicle arrives at your facility. In addition, be aware that Toyota’s repair procedures may differ from other manufacturers — that’s why it is critical to follow the Toyota procedures.