GM and Honda have announced the start of production at their 50-50 joint venture production facility, FCSM. FCSM is the first large-scale manufacturing joint venture to build fuel cells.

FCSM was established in Brownstown, Mich., in January 2017 based on a joint investment of $85 million. The 70,000-square-foot facility has already created 80 jobs. The world-class hydrogen power solutions built at FCSM will be used by both companies in various product applications and business ventures.

“This is a historic day for the industry as GM and Honda are the first full fuel cell system manufacturing joint venture to begin volume production of fuel cells for transportation and beyond,” said Suheb Haq, president of FCSM. “We begin the process with raw materials for membrane and electrode all the way through completed systems. Ongoing investment and commitment by both companies is driving our success at FCSM. This commitment aligns with our mission of making high quality, durable and affordable hydrogen fuel cell systems for a wide range of applications and customers.”

Added FCSM Vice President Tetsuo Suzuki, “We integrated the strengths of Honda and GM to create the most capable production system at this joint venture. We brought a mass production mindset with attention to detail and a focus on high quality, and now we are ready to meet the needs of the customers for the future applications of fuel cell technology and the beginning of the hydrogen era.”

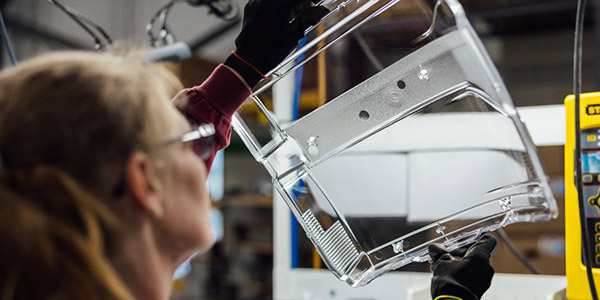

Honda and GM engineers began work in 2013 on the co-development of the next-generation fuel cell system. In addition to advancing fuel cell system performance, GM and Honda collaborated to double durability compared to the 2019 Honda Clarity Fuel Cell by using corrosion-resistant materials and by improving low-temperature operation.

Together, the two companies also focused on lowering development and manufacturing costs by leveraging economies of scale, advancing the cell design, simplifying supporting auxiliary equipment, utilizing common sourcing and reducing the use of costly precious metals. Through this collaboration, the new fuel cell systems will be one-third less expensive to make when compared to the cost of the fuel cell system in the 2019 Honda Clarity Fuel Cell.

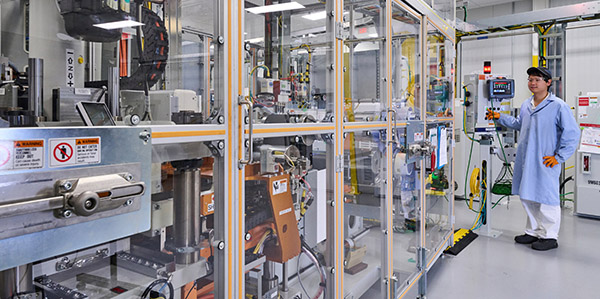

Significant efforts have also been made at FCSM to ensure the highest levels of quality while improving manufacturing productivity. The venture incorporates many first-of-their-kind methods for automating membrane-electrode-assembly production and fuel cell stack assembly.

Both the GM and Honda engineering teams and the companies’ relevant intellectual property and expertise have been integrated at FCSM to create affordable, commercially viable hydrogen fuel cell systems to be utilized in a variety of zero-emissions propulsion and energy management applications.

GM and Honda share in the belief that hydrogen and fuel cell technology will play an increasingly important role in meeting a wide variety of zero-emissions energy and mobility needs.

For more information on FCSM, click here.