Technicians performing calibrations on vehicles equipped with ADAS features face many variables in their daily work. Troubleshooting through these variables can be time-consuming and test everyone’s patience.

Many people in the automotive repair industry think it’s about just plugging into a vehicle and clearing codes. One shop recently told me they believe as long as there are no codes or lights on the dash, it’s good to go. Ironically, this same shop was telling customers that they follow all OEM procedures in repairing vehicles. This thought process is still prevalent throughout the industry. Educating the industry and consumers is still an ongoing process that we all must do.

Misconceptions

This thought process also affects the understanding of what it takes to do a calibration. There is a misconception out there that there is a wonder scan tool that can do all vehicle’s calibrations with no problems whatsoever. I would like to see that scan tool. The reality is that there are some good scan tools out there. They all have different strengths or weaknesses in their operating software or calibration processes. The OE software is also available, but you’ll end up maintaining a good deal of software subscriptions and equipment.

The biggest misconception I see is that the tool does everything for you. A majority of the time, calibrations are fairly straightforward, but what happens when they’re not? Many people follow the 80/20 rule. If it works 80% of the time, then you’re good. The issue I see is that 20% of the time, there are issues that take 100% of your frustration time for everyone in the shop — including the customer. The situation then rapidly shifts to a high-stress, “What do we do?” mode. Your technician’s skill level will be a major factor in the outcome. Keep in mind that you can train someone to use equipment, but experience comes with time.

The Struggle is Real

A technician is working on a 2022 Mitsubishi Outlander that has had the windshield replaced using the tool his company purchased for doing calibrations. He or she is struggling with the calibration; after check- ing the setup and information they’ve been provided in the scan tool, they’re getting a code C2503-54. What are the next steps?

- Verify that the camera is mounted correctly to the glass

- Be sure the connection to the camera is correct

- Check surroundings and light to meet OE requirements

- Is the floor level?

- Have all vehicle requirements been met?

There are a few more things to check that can be added to this list. Let’s assume all the items have been checked. What is the next step?

- Research what the code means

- Look up the OE service information and compare to the scan tool’s service information provided

- Contact the scan tool manufacturer for support

- Send to the dealer

This is where a technician can get frustrated as the customer wants their vehicle and the shop has more vehicles to be done, so the stress builds. Where do you go for information? Does the scan tool offer any type of support for technicians? Do you have access to the OE service information? In this case, after comparing service information from Mitsubishi to the scan tool being used, it was found that there were three different models of Outlanders with different static target setup procedures and measurements for doing the FCW/LDW camera calibration for each model.

A great deal of time is spent researching when challenges arise. Technicians can be faced with many variables, from software issues to bent brackets or damaged wires. With a newer vehicle, a common problem could also be that the scan tool may not have access or the ability to access the correct modules to complete the calibration. Updates for that software may not be available yet.

What’s Wrong?

Here’s another scenario, this one on a 2017 Chevrolet Bolt. The shop called to have a calibration done on the blind spot module (BSM) after the vehicle was involved in a collision. The vehicle suffered damaged on the passenger rear quarter. The rear bumper was replaced during the repair process. Upon completion of all repairs, the shop set up for a BSM calibration, the technician did a scan and no DTCs were stored. The BSM was replaced on the passenger side due to the extent of the damage. The technician programmed the module successfully, adding the cost of programming to the calibration. During the test drive or drive cycle to verify that the systems were operational, the technician noted that when a vehicle passed by from behind on the driver’s side, the indicator light on the mirror stayed on after the vehicle passed. It was also noted that the passenger side radar did not register the vehicle passing at the same time the driver’s side radar did — it was indicating much later than the driver’s side blind spot radar.

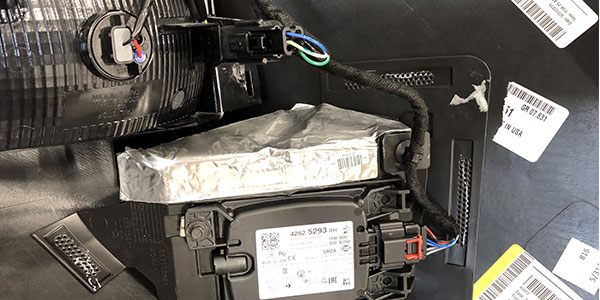

This is the kit that was ordered for the radar foil that made the difference in a calibration of a 2017 Chevrolet Bolt. When you order the radar module for replacement, you would need to know to order the radar foil as well.

Note: This scenario is the reason why calibrations and a test drive must be completed to verify that repairs are done correctly and all systems are working properly. Assuming that no DTC codes verifies that no problems exist in the vehicle is a myth when working with vehicle safety systems. A technician performing a test drive or drive cycle needs to understand the operation of the vehicle’s systems to validate that they’re working properly.

Research on the shop’s damage estimate indicated that one module was replaced and the other module R&I’d during repairs. In this process, aluminum tape that was on the radar modules was removed. Since the technician performing the calibrations did not see the tape before repairs were made, they did not notice it was missing. After the bumper was removed, the bracket mounting rechecked and the harness and connections as well as paint thickness and stickers on the bumper that could affect radar were checked, more research was done. It was found that an aluminum tape is used on the radar module to “focus” radar waves for proper operation. Once the tape was properly applied to the radar module, the system operated correctly during the test drive.

Bent Mounting Bracket

A 2017 Infiniti was involved in a front-end collision. The front bumper was replaced and painted per the estimate. The repairs called for a calibration to be completed as the adaptive cruise control radar was replaced due to damage. The technician completed a scan with no relevant DTCs and went on to complete the calibration. The calibration failed, with the error showing no target detected. The shop was asked to remove the front bumper as it was freshly painted. Upon removal of the bumper, an inspection was done to verify that the radar was aimed correctly and it was found that the mounting bracket was bent. The technician tried to straighten the bracket as good as possible. The shop was asked to order a new bracket and, when the bracket was ordered then replaced by the shop a few days later, the calibration was successful. The delay to the customer and the time spent fixing the problem could have been avoided.

A Lot to Learn

There is a lot to learn about what it takes to repair today’s vehicles. Programming, calibrations and diagnostics have all added to new metals, welding concerns and battery electric vehicles. There will be pitfalls and victories as all of us learn our way through these repairs. Knowing that there will be challenges is one of the best mindsets you can have. Patience in learning with technicians to gain experience in what needs to be done will be difficult when you’re trying to get vehicles out the door. Addressing the needs for the electronics such as calibrations and test drives and scheduling to have the right amount of time if the 20% in the 80/20 rule kicks in will save you some frustration. Who does your test drives or drive cycles? You or the person doing the calibration or service? That’s something to think about.