Whether you’re a body shop, auto glass shop or even subletting to a company performing services for your shop, when you’re repairing any vehicle, you need to know what, how and why to complete the repairs correctly and efficiently. Knowledge is key to your business success and your customers’ safety.

In the world of automobile repair, change is happening at a rapid rate, challenging everyone as there is so much to learn. There is so much to consider beyond welding, painting, structural repairs and electronics that it is amazing and sometimes frustrating to all of us.

The other challenge is there is a great deal of misinformation being distributed. We all see the videos of people on social media showing what they think is a great way to repair a vehicle or complete a process. I know all of us have watched these videos and thought: What are they thinking? With this in mind, you would not let any technician in your shop cut corners, so what about your sublet? Does it matter?

Whenever you work on a vehicle that a family has entrusted you to repair, remember that they’ve put blind faith in you to do the right thing and repair their vehicle correctly. They may not know the difference between a cosmetic repair and a structural repair or how a safety system works in their vehicle. The family may not understand how or why the repairs must be done correctly; they just put their trust in you that you know what to do and will protect them, whether you are replacing a windshield, welding on a quarter panel or repairing a bumper cover. What you do and how you do it makes a difference. On the vehicle you’re working on, picture a nine-year-old child sitting in that back seat. What does that kid have to lose if you do not do your job correctly? Think also of the safety of the parents in the front seat. When you think of it this way, fixating on the difference between “recommend” or “require” in the original equipment (OE) repair procedures seems kind of silly.

Why?

Doing anything in life is difficult when you do not know why you must do what you do. Why does a weld have to be correct? Why do the instructions recommend this? Why do the instructions tell me I have to calibrate this system? Without the why, it is easy to overlook the importance of what may be considered a minor or insignificant detail.

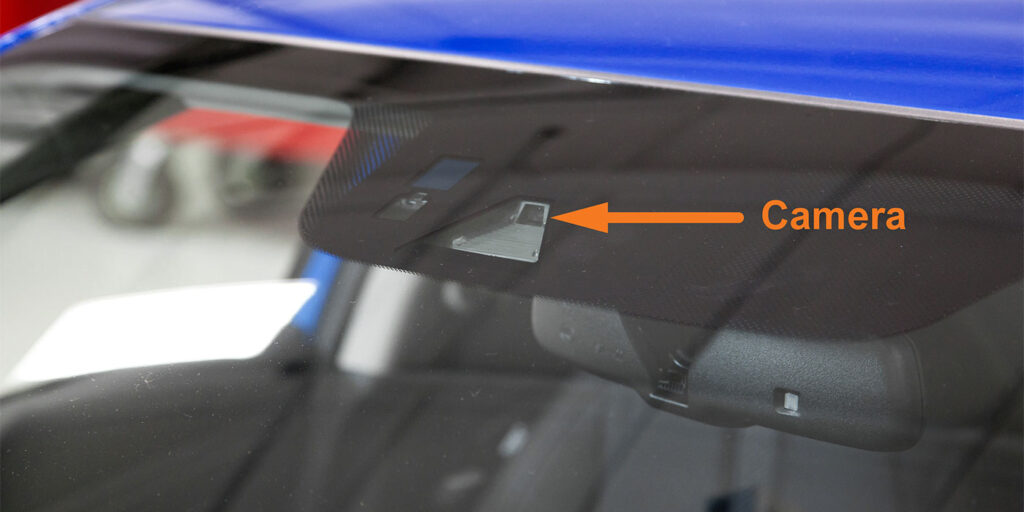

I see so many companies still not doing pre-repair scans on vehicles before repairs are made, particularly in the auto glass industry. The comment that “We are just replacing the windshield” really shows that somewhere along the way, the why was never explained. Auto glass companies that have had to replace the forward-facing camera after a windshield installation have learned quickly that pre-scanning the vehicle may have revealed a diagnostic trouble code (DTC) indicating the camera was not functioning correctly before they pulled that camera from the windshield mounting bracket. Without verification prior to work being done, the realization of having to fix something that was pre-existing can be very expensive. A pre-repair scan is similar to why we take photos prior to working on a vehicle — to indicate any preexisting or unrelated prior damage. A pre-repair scan is like an X-ray in that it allows you to see inside the vehicle electronics to identify any problems you need to be aware of. Keep in mind that many of these cameras are also a few years old, and we all know wear and tear as well as heat and cold can do some amazing things to electronic components. That pre-repair scan is becoming more important every day.

It’s not just the pre-repair scan that is important — a technician will need to understand if any DTCs are present that will prevent a calibration from being performed in related systems. Not understanding what the codes are telling you can stop a technician from completing vehicle repairs correctly. Many body shops and glass companies have learned that, many times, the equipment will successfully complete the calibration — but when they do not complete the calibration, that’s when the technician’s troubleshooting experience comes in. Knowing how and why electronics work and how to repair them is a necessary skill beyond just doing calibrations.

With ADAS systems, there are still many shops and technicians who do not know when and why calibrations are needed when the camera is removed from the mounting location. I also see technicians in the glass industry replacing windshields where the camera is hanging from the wires from the roof or headliner. Why is this being taught, and why is it considered acceptable? First, the instructions say to prevent damage to the camera, disconnect it and remove it from the mounting bracket. That’s pretty self-explanatory. The camera can be damaged by the shock of being bumped and by getting debris or even fingerprints on the lens. The reason some techs leave the camera hanging is, “If I do not disconnect the camera, I will not need to calibrate the FCW/LKA/LDW camera.” The fact that the calibration validates that the camera is connected, mounted and aimed correctly for the systems to perform in the event of a road hazard has not been fully explained to the technician. Without these whys, it seems okay or acceptable to leave that camera hanging.

Body shop technicians seem to have the same thought process when it comes to hanging a bumper cover and not disconnecting connectors for sensors, radars and lights. Also, for side mirrors on doors equipped with blind spot cameras. When technicians or shops do not follow instructions or do not know the why, we set ourselves up for an unhappy customer or possibly something worse.

People

Take a survey of people around you and ask how many of them have ADAS features on their vehicles. Then, ask how many have had the systems warn or react and work exactly as they should to prevent a collision? I bet you’ll learn just how much people are becoming dependent on these safety features. Making sure the systems are aimed and functioning correctly is becoming more and more important. Not that it wasn’t before, but with more vehicles requiring not just one but multiple calibrations per repair, research to know what, when and why calibrations must be completed are necessary to complete the vehicle repairs correctly. Not validating these systems because you thought they only needed calibration if you unplugged the sensor can be devastatingly wrong.

People may not understand how their vehicle safety systems work. Many are still confused on why a windshield replacement on vehicles made today is so different than their last car. But if it drives differently after you’ve completed repairs, the owners will know it and may or may not let you know something is wrong. But I caution you, if something happens, they will know who to blame for the issue. There are many companies that are still only doing the glass replacement and having customers sign waivers if the customer refuses to pay for a calibration after the vehicle is repaired. That is a business decision not to be taken lightly. I suggest consulting with your company attorney before making any decision on what you decide. There are times when a calibration just can’t be done correctly. Modified vehicles present problems to companies every day. In doing your research, you may find some OE manufacturers do allow calibrations on vehicles that have been modified. Equipment requirements or other vehicle specifications need to be followed as to when it can be done.

Clearing Codes

There are way too many people in the automotive repair industry who feel that if they clear all the DTCs in the vehicle, it’s ready to go. Another similar thought is that if the shop clears the codes and drives the vehicle for a mile and no DTCs return during a post-repair scan, the vehicle is ready to go. The calibrations are the zeroing and aligning of sensors to effectively sense the road for hazards. If the sensors or their position of alignment is compromised or set wrong by a technician, the vehicle will not perform correctly. The thought that a DTC will be set if the vehicle is not calibrated correctly is not true. There are times when the vehicle does alert that there is a problem, but in most cases, the vehicle relies on the shop to complete the calibration and test that it’s performing correctly.

Summary

Whether you’re an auto glass company or body shop, documentation is a critical step to proving you did the job correctly. In reviewing any shop’s documentation, I look at the mileage in and mileage out. If the difference is a mile or two, I can assume that a test drive was never completed to the extent of testing the vehicle systems correctly. A lot of vehicle service information requires that vehicles be driven for periods of time at certain speeds with proper roadway markings. These dynamic road tests are required to make sure all systems are performing correctly. I see this step skipped by many shops, as it’s a huge inconvenience. The importance of this step should not be overlooked. I’ve seen many vehicles fail the dynamic testing after passing the static calibrations. Software issues, programming or, many times, technician error in placing targets can be the root causes of these failures. Without properly validating operation, you may be putting that nine-year-old in the backseat at risk. Please don’t be that shop or person.