Name: Dick’s

Body Shop

Location: Yuba

City, Calif.

Owner: Dick

Sanchez

Established: 1960

Square Footage:

53,000 square feet, includes body shop, truck repair, RV repair,

office space and NAPA Auto Parts store

Number of Employees:

50

Repair Volume:

Approximately 200 cars and light trucks per month

Average Repair Ticket:

$1,300 to $1,400 for cars and light trucks

Wilbur Avenue.

That’s the name of the street in Yuba City,

Calif., where Dick Sanchez’s body shop is located. One look down

the street, however, makes you wonder why it hasn’t been renamed

"Dick Sanchez Boulevard."

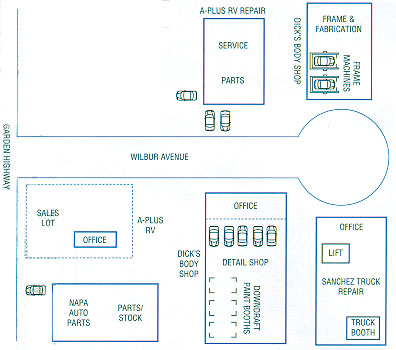

As you turn off Garden Highway onto Wilbur,

it becomes evident that Sanchez is a successful businessman. On

the right is Sanchez’s A-Plus RV, a new- and used-RV dealership;

directly behind that business is his NAPA Auto Parts store; and

further up the street, attached to a two-story office building,

is one-half of Dick’s Body Shop, where paint, body and detail

work are done. (The body shop is the only NAPA AutoCare Collision

Center within 50 miles.) Located at the end of the street, which

ends in a circle, is Sanchez Truck Repair in a two-story office

building. Across the street is the other half of Dick’s Body Shop,

where frame and sheet-metal work and front-end alignments are

done. Working back toward Garden Highway, the next building is

A-Plus Service, Parts and Repair, where Sanchez repairs RVs.

In total, Sanchez has more than 53,000 square

feet of shop, store and office space spread over 12 acres – a

total that doesn’t include the commercial buildings he owns, which

are across the street from the A-Plus sales lot.

And if that’s not enough to convince you that

he "owns" the street, you should know that Sanchez actually

put most of the road in himself, including the underground infrastructure.

Obviously, things are going well for Sanchez,

but that certainly wasn’t always the case.

From Broke to In Business

When Sanchez graduated from high school in

Yuba City, he and a friend were ready to chase the "American

Dream" – or at least a decent paying job. When they heard

that Douglas Aircraft in Los Angeles was hiring, they decided

to mix adventure with practicality and hitchhiked there.

"I was 18 and too young to know any better,"

says Sanchez. "We were so broke we had to rent at a boarding

house on credit, the credit being the check we would receive on

our first pay day."

Having earned his first check from Douglas,

he would never be broke again. In fact, he started working on

cars on the side, which gave him a little extra spending money

and a chance to do something he liked to do.

In 1958, Uncle Sam called, and Sanchez reported

for duty at Fort Ord in Monterey, Calif. After boot camp, he was

stationed at Fort Sill, Okla., where he continued his car-repair

moonlighting. It was here that his "American Dream"

started to get bigger, even though the shop floor was made of

dirt and a small electric fan was the exhaust system for his homemade

paint booth. But as he saw it, his body work was the most redeeming

experience he had in the Army.

After the service, Sanchez took a job as a

body man in a Sacramento body shop. In 1960, wth this experience,

he decided to make his dream a reality by opening his own shop.

"I didn’t know what I was getting myself into, but it sounded

like a good idea at the time," says Sanchez. "The business

was basic; I sanded by hand. In fact, I did everything by hand.

When I look back, I do wonder how I did what I did."

There’s no doubt that his beginnings were humble, but it didn’t

matter to Sanchez. He was doing what he wanted to do. "My

customers appreciated what I did for them," he says. "It

doesn’t get any better than that."

No Secret to Success

Obviously, Sanchez’s business has grown at a phenomenal pace over

the years. When asked what his "secret of success" is,

he gets very serious and downplays his success. "I don’t

think there are any secrets," he says. "It’s just a

matter of hard work, determination and commitment. There never

was a time when I turned a customer away because he or she was

too demanding. We treat the customer as ‘king,’ and everything

else just falls in place."

The key to treating customers like kings is in "reading"

the customer correctly – a point that Sanchez says is often misunderstood

if just taken at face value. "Each customer is unique, and

each job is unique," he says. "Not everybody wants or

needs the type of finish that would be used on a ’98 Lexus. Just

as some cars are more expensive, so are some finishes. This doesn’t

mean we compromise the quality or the service, we just figure

out what level each customer wants. For example, if a single mother

comes in here on a fixed income and wants her car refinished,

we find a way to do it that works for her and for us."

Another thing customers want these days are modern, clean waiting

rooms and restrooms, and according to Sanchez, it isn’t even a

dirty business on the shop side these days. "Anyone who stops

in is curious of where they’re getting their car repaired."

he says. "If the place looks like a dump, they figure it

probably is. The way I figure it, a professional-looking business

just keeps you even. The rest is up to how well you can communicate

the advantages of your shop."

As a matter of fact, Sanchez uses the condition of his business

– out front and in the shop – as a sales tool. He personally takes

customers on tours of the entire shop so they can see, first hand,

the care that his workers take on each individual car, truck or

RV. "Most people don’t have a clue as to how we do this work,"

says Sanchez. "A tour personalizes the work because they

visualize their car in here and then the next logical step – they

visualize it after it’s been repaired."

Upon completion of a job, an employee runs through a final check

of the vehicle to be assured all repairs have been completed and

all lights and accessories are working properly. The office staff

then advises the customer of the warranty and provides each customer

with a postage-paid evaluation card when the vehicle is picked up.

An Equal Opportunity Competitor

Sanchez is what you might call an equal opportunity competitor.

As mentioned earlier, Sanchez owns two large commercial buildings

alongside his auto and truck businesses – in which he rents out

space to a number of business, including three auto mechanic shops.

And he sees this as more of a help than a hindrance to his business.

"Although 25 percent of my overall business is mechanical

repair, it’s associated with the collision repair business,"

says Sanchez. "I’m not looking to do a lot of mechanical

repair outside of the collision repair, except for some of my

long-time customers who won’t let anybody else work on their cars

– I just can’t say no to them.

"Taken as a whole, renting space to these shops actually

helps drive my NAPA store business. They buy from me because it’s

convenient, and we can supply their needs better than anyone else.

If there’s competition, it’s more between the three of them, rather

than between them and me. This wasn’t done by design, but it seems

to work for everybody. Their shops have followings just as we

do. It’s a great arrangement."

Another benefit of running the NAPA Auto Parts store is that Sanchez

is his own best customer. "How can I go wrong selling quality

products to myself? If there ever was an ideal setup, I’ve stumbled

upon it," he says.

To help stay on top of the business, Sanchez gets new-product

demonstrations from his NAPA/Martin-Senour rep, who also keeps

him up to date on any price increases; Sanchez is prone to buying

large quantities before a price increase, which, in effect, saves

him a lot of money.

Also key to his productivity and profitability is the Color Dominator,

NAPA/Martin-Senour’s color spectrophotometer. "I don’t know

how I ever got along without it," he claims. "We used

to do a lot of sprayouts searching for that blendable color match,

which, of course, was an imperfect and time-consuming method.

Now we push a button and, in under a minute, the Dominator gives

us the right formula."

Other pieces of equipment that aid his body shop business are

two Chief EZ Liner frame racks, a Dataliner laser measuring device,

two Quadraft downdraft spraybooths, two DeVilbiss jamming booths

and a Chief Genesis electronic measuring system.

In addition to having the equipment needed to stay productive

and profitable, Sanchez has five insurance companies for which

his body shop provides direct repair. And though he has this insurance

business from which to draw, he still advertises heavily on radio,

television, newspaper and at local athletic events. "There

are no guarantees in this business of when the next customer will

come through the door," he says. "As everyone knows,

the best form of advertising is the work you do that other people

see; but not everybody gets to see it, so we think it’s a worthwhile

investment to advertise as often as we can."

Sanchez admits that it can be challenging to work with insurance

companies, however, he says the real key is to work with the individual

adjusters. "I’ve never thrown an adjuster out of my office,"

he says. "One on one, we can work out any difference of opinion."

All in the Family

Both of Sanchez’s children grew up in the business. It was a fun

place to be as children since there was always so much happening,

but the longer they were involved, the more it seemed like work.

So after they both went to college, they were determined not to

be in the family business. Sanchez’s son, Rich, earned his C.P.A.

and went to work for a fertilizer firm, and his daughter, Debra

DeWitt, went to work as a welfare case worker. But within a few

years, both came back to work with their dad: Rich manages the

NAPA Auto Parts store, and Debra is the corporation’s office manger.

"It was important for them to establish their independence

and work for someone else," says Sanchez. "They learned

to appreciate just how well they had it here and, after giving

it a great deal of thought, they decided they actually liked the

work they had grown up doing."

Of course, Sanchez was happy to see his children get back into

the business. "It’s all going to be theirs someday,"

he says, "so the better they can run it now, the better they

will run it later."

In addition to his two children, Sanchez has 48 employees. He

has several 20-plus-year employees, but he hasn’t yet found what

he would consider the best incentive plan. Having tried many different

plans, it seems to just come down to treating his employees as

family.

"It’s a family-owned business, and the people who work for

me are an extension of my own family," says Sanchez. "Overall,

it seems to be the little things that matter the most to them."

For example, Sanchez has a company limousine that he uses for

employee special occasions, such as weddings and birthdays. "It

makes them feel special, and I think they really appreciate it,"

he says.

Being part of the family also means taking a serious attitude

about the job. All of Sanchez’s employees attend seminars regularly

and the body men are I-CAR Gold and/or ASE certified. Painters

also attend a week of training in Reno on a regular basis.

Sanchez also takes industry involvement for himself seriously.

He is a member of ASE and the California Auto Body Association

and has been an auto body instructor at a local community college.

Moreover, he has sponsored I-CAR Gold training at his shop.

His Road of Success

So what kind of encore is there for Sanchez? New-car dealerships?

Quick-lube franchises? A racing team?

Being more humble than that, he just wants the opportunity to

earn the business of the next customer who walks through the door.

And, if and when he decides to add yet another business to his

résumé, he’ll also need to add a new street – Wilbur

Avenue is full.