Name: Champ’s Collision

Centers

Location: Six shops in

New Orleans

Owners: Danny Kingston

and Ronnie Lamarque

Established: 1977

Square Footage: 40,000

square feet (largest of the six)

Number of Employees: 147

Repair Volume: Approximately

1,000 cars per month

Average Repair Ticket:

$1,200

Caring about customers and his employees has landed

Danny Kingston the largest body shop operation in New Orleans

– and, possibly, in the whole state of Louisiana.

Kingston, along with partner Ronnie Lamarque, owns

Champ’s Collision Centers, which consists of six locations strategically

located on both sides of the Mississippi River and Lake Pontchartrain.

This captive customer base seems to be a result of Kingston’s

business philosophy, the stock he places in people and the strategic

planning of the locations.

A Business Approach

It was actually Kingston’s business sense that drew

him to the collision repair industry. While in high school, he

worked a summer job sanding and painting cars. A few years later,

during Kingston’s senior year in college, he and lifelong friend

Chris Antonatos started Champ’s because Kingston says he noticed

that people operating body shops weren’t managing them as businesses.

A year after starting Champ’s, Kingston – who was

still in college and starting a family – Kingston went to work

for Lamarque Ford, where he managed its body shop for 15 years.

During that time, Champ’s continued to grow, and Antonatos found

himself in need of an office staff and financial expertise to

move forward. Kingston and Lamarque provided that expertise by

buying Champ’s.

That was five years ago.

Now – five additional locations and seven insurance

companies later – Antonatos concentrates on running the original

location while assisting with the others, and Kingston and Lamarque

take care of the financial and organizational needs of the business.

In particular, Kingston works to keep the company stable and ready

for the future, works with his managers to ensure they have the

necessary tools and capital needed to stay on top of the industry

and tries to keep overhead as low as possible – but not to the

point of affecting quality. This philosophy is what Kingston thinks

sets Champ’s apart from other autobody enterprises.

Keep ‘Em Coming Back

Quality, as always, keeps customers coming back.

As a matter of fact, quality work and word of mouth is Champ’s

main form of advertising, with the help of some billboards and

an ad in the Yellow Pages.

And not only does quality keep customers coming back,

but it helps keep technicians coming back, too. "Our [technicians]

know we’re going to fix the car correctly, or we’re just not going

to fix it," says Kingston, adding that this is what his techs

like the most about the company; they have confidence in the company’s

commitment and in its professional office staff to get the proper

amount of money to fix cars correctly and to pay them for their

work – allowing them to concentrate on the jobs at hand.

"It’s a lot easier if you know when you come

to work that you’re going to do everything the right way and you’re

not going to cut corners," says Kingston. "A good technician

will want to work for a company that he knows is going to stand

up for the right [way to fix automobiles.]"

This, Kingston says, is one reason Champ’s is able

to attract and keep good people – which are the backbone of this

successful business. In fact, about 90 percent of the good technicians

the business has lost have come back to work for Champ’s, "so

we’re really blessed with probably the best technicians in New

Orleans," says Kingston, adding that having six locations

also helps to attract and retain techs because it gives them options:

to work at a shop that’s close to home or to transfer to one of

Champ’s other locations.

Being able to run six shops is the result, Kingston

says, of growing good people. How does he find these good people?

According to Kingston, his greatest success has come from starting

with honest, hard-working people, trying to move them along and

allowing them to better themselves.

Kingston prefers to promote within his business,

rather than recruit people from other body shops with different

philosophies. As a matter of fact, most of his shop managers came

to Champ’s as appraisers. "Body techs and painters generally

find us," he says. "Good people attract good people."

Investing in People

All Champ’s technicians are I-CAR trained, and the

shop is part of the DuPont Assurance Of Quality (AOQ) program

and is an ASA member. Also, Kingston encourages International

Autobody Congress and Exhibition (NACE) attendance (mandatory

when in New Orleans) and has adopted in-house training.

In addition to giving "older" technicians

various financial incentives or perks for working with younger

technicians to teach them the trade, Kingston has arranged for

a "seasoned tech," a shop foreman, to go from store

to store to make sure technicians are up to date, ensuring they

know what’s expected of them and helping them strengthen any skills

they’re lacking. "I feel this will help them tremendously,"

says Kingston. "Hopefully, within a year, he will have made

it to all the shops."

Another type of testing Kingston has implemented

– which, when you get right down to it, shows that he cares about

his business and his employees – is drug testing.

Feeling there was a need to protect his good employees

and his business from drugs, Kingston recently decided to test

his employees. "Now that it’s over with," he says about

Champ’s first try at drug testing, "I think some of the guys

are very glad we had the program because now they’re ensured that

they’re working side by side with people who are drug free. …

Their families are going to be the big winners."

And to ensure newcomers will also be drug free, Kingston

plans to drug test before hiring. "From an insurance standpoint,

it makes very good sense. … [It could be] a dangerous situation

if you don’t have all your faculties when you work on cars,"

he says. "[And you have to take into consideration the] quality

of repairs. It just seemed to make sense; drugs lead to theft

and a lot of other things we just can’t tolerate."

Quality People Need Quality Equipment

Another way Kingston upholds quality is by acquiring

quality equipment. Champ’s has made large investments to ensure

cars go through the repair process quickly. About two years ago,

$300,000 was spent for one location’s paint department to ensure

it could handle the desired volume.

Concerned about the timeliness of repairs, the owners

have outfitted Champ’s with Spraybake paint booths at all the

locations – most of the locations having two booths. "It’s

really helped us set up to go forward," Kingston says. "We’re

in a position now where we can get cars in and out fairly quickly."

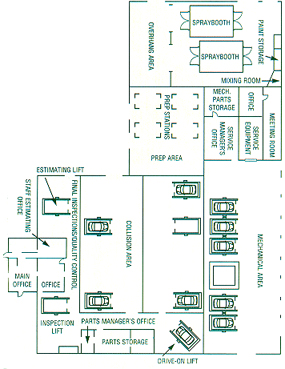

In addition to Spraybake spraybooths, Champ’s relies

on Car-O-Liner dedicated unibody benches, CCC and ADP computerized

estimating systems and several computerized management systems.

A Flood of Work

The Big Easy, separated by various bodies of water,

gets a lot of rain, which can be a recipe for disaster: disaster

in the form of floods.

The last flood, which occurred in May ’95, almost

ruined Champ’s. Kingston had several insurance companies asking

him to take on 600 to 700 cars. The problem: In addition to not

being equipped for that kind of volume, Kingston says his employees

were overworked. To keep up with the volume, says Kingston, Champ’s

employees worked through every night for a month; but, by the

time employees were compensated and dinner was bought for all

those working, not much money was really made. His shops might

have made $5,000.

Looking back, Kingston says he would’ve rather paid

someone else $20,000 to do the work – just so his employees could

have gone home to be with their families. "It’s something

we did and will continue to do because it helps the community,"

says Kingston. "If we weren’t to attend to those needs, I

don’t think we would’ve been a very good business."

On the positive side of things, when it isn’t causing

floods, rain can be good for business. "If there hasn’t been

rain for a couple of weeks, I think people forget how to drive

[in it]," Kingston says with a laugh. And, though business

doesn’t usually fluctuate very much throughout the year, Kingston

remembers two or three times New Orleans was showered with ice,

which "pumped up business because no one knew how to act

in it."

Are You Crazy?!

Another event special to New Orleans is, of course,

that big party in the streets known as Mardi Gras.

But does it affect business as usual?

Sort of, but not by bringing in increased business

due to drunken mishaps; it only ends up postponing some repairs

because many people hold off until after the celebration if their

vehicle is still driveable. "There’s a lot of excitement

in the city," Kingston says. "For about a two-week period,

everybody’s interested in Mardi Gras and not interested in taking

care of their vehicle needs. … But it’s tradition, you know,

so everybody kind of tolerates it."

Though Mardi Gras brings in a lot of out-of-towners,

Kingston says only a few of them visit the shop after a car theft

or collision.

Kingston says he doesn’t remember any one particularly

interesting Mardi Gras repair … "Nothing really stands

out," he says. "But with all the wild stuff – people

getting killed, people going crazy – but nothing that really stands

out."

Kingston does, however, remember one "crazy"

repair, which wasn’t, believe it or not, a result of Mardi Gras:

A man rented a car – and then went crazy. According to Kingston,

the man thought the car was a bull and "rode" it. The

man – or shall we say, the "bull rider" – bent the car’s

windshield wipers forward (perhaps to imitate bull horns?), placed

napkins on the vehicle’s carpets and then packed the car with

mud. With no other options, police resorted to drastic measures,

shooting at the rodeo action taking place up and down a levee.

When the car finally arrived at Champ’s, techs had

to remove the mud and repair the bullet holes. The total repair

bill: $6,000.

"This guy was just nuts," says Kingston

after sharing his story. "But anyway, nothing that really

stands out."

Writer Eileen Benedict is associate editor of

BodyShop Business.

| From a Business Standpoint

BSB: Do you consider yourself DK: "A businessman."

BSB: How do you make sure

DK: "There are a BSB: Do you job cost?

DK: "Yes, but I don’t

BSB: What were last year’s DK: "Around $12 million."

BSB: What do you do with

DK: "Reinvest, naturally,

BSB: Do you get financial

DK: "Yes, I do. We

BSB: If you could give

DK: "Invest in your |