Before the Ford F-150 and F-Series Super Duty trucks shifted to an aluminum-alloy body, repairing the front apron tube on either truck was a daunting proposition.

Ford describes the previous front apron-tube repair on the F-150 and F-250 Super Duty as “a complex, invasive operation” that required the repairer to tear down the truck’s A-pillar and remove the entire instrument panel.

“This was a real beast of a repair, one that I personally received a lot of feedback on and was asked if there was anything that could be done about it,” Gerry Bonanni, Ford senior damageability engineer, explains in Ford’s latest On Target newsletter.

Ford took that feedback to heart when redesigning the popular trucks. Both vehicles now incorporate “upstream designs to enhance and improve overall repairability,” Bonanni explains.

“The apron tube on both vehicles has been pulled further out from its original location inside the vehicle and is now much easier to access,” Bonanni says. “Repairers no longer have to remove the A-pillar or even touch the instrument panel. This new, modular design not only makes the overall apron-tube repair easier and more straightforward, it now saves an incredible amount of time – up to seven or eight hours.”

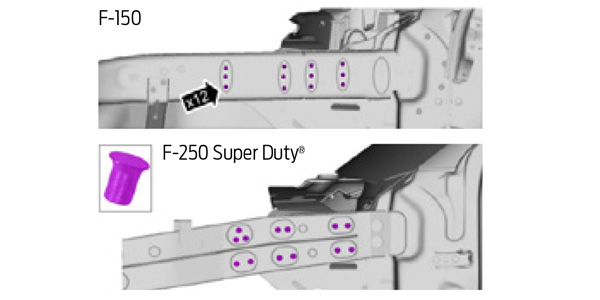

Bonanni notes that there are similarities and differences between the 2017 F-150 and F-250.

As for similarities, the front apron on both vehicles must be replaced at factory seams only, and sectioning is not permitted.

However, the apron tubes on the F-150 and F-250 are made of different materials. The apron tube on the F-150 is a hydroformed aluminum component, while the apron tube on the F-250 is hydroformed HSLA-350 steel.

“To prevent the steel and aluminum from interacting with each other, the steel apron tube on the Super Duty – along with the rivets, fasteners and adhesives – are all isolated by a special powder coating,” Ford explains in its On Target publication. “That coating also appears on all genuine Ford replacement parts, guaranteeing a robust repair.”

The apron-tube installation techniques also are different. On the F-150, rivets are the only approved installation method, and welding isn’t permitted. On the F-250, however, MIG and plug welds are allowed as the repairer sees fit. In addition, the apron tube on the Super Duty can be separated at weld-joints to meet repair needs, according to Ford.

As with any repair advice, Ford emphasizes that the information is intended as a general guideline. The automaker urges repairers to conduct thorough research before making the repair.

Repairers can find more information in the official Ford Workshop Manual, Section 501-27: Front End Sheet Metal Repairs – Fender Apron Panel Reinforcement, which can be accessed through Motorcraftservice.com.

Both apron-tube repairs also are detailed in specific instruction sheets: Sheet No. SKFL34-16E060-AA for the F-150, and No. SKHC3B- 16E060-AC for the F-250. They can be found at OEM1Stop.com and I-CAR.com.