The panels were welded

on at the factory, and logic dictated that we would use a similar

method during panel replacement. Before the unibody revolution,

gas welding, brazing and resistance panel spot welding were widely

used.

Later on, when vehicle manufacturers were

confronted with governmental fuel-economy regulations and a diminishing

market share due to Japanese competition, they quickly introduced

an entirely new vehicle – which brought a whole new group of alloys

into play. Who ever heard of high-strength steel? Martensitic

steel? And what do you mean I can’t heat it to straighten it?

Gas Metal Arc Welding (MIG) quickly became

the method of choice as welder manufacturers recognized the new

market potential that accompanied this welded sheet-metal unibody

vehicle. No longer was there a heavy frame to give strength and

rigidity to the automobile.

Those of you who were in the business in the

late ’70s will remember the madness that accompanied the unibody

introduction. Shop owners, technicians, suppliers and equipment

vendors scrambled to embrace new equipment, new methods and what

really amounted to a whole new vehicle repair philosophy. MIG-welding

seminars held by distributors featured complete front ends of

unibody cars that were brazed together by some unknowing, untrained

technicians and were literally unsafe at any speed. Insurers paid

for thousands of re-repairs to vehicles that were compromised.

What a time it was!

As the industry got up to speed, things calmed

down. Vehicle manufacturers recognized the need for research and

for communication with the repair industry. I-CAR was founded,

training for this new generation of vehicles was introduced and

a new level of normalcy was upon us.

But, alas, nothing lasts forever …

As vehicles got lighter, more of the vehicle

components came into play as secondary structural components.

Front and rear windshields were now bonded with urethane instead

of butyl, and more sealing was done for rigidity, sound deadening

and to create a watertight seal.

Certain aspects of this OEM technology were

transferred by several manufacturers and marketers of adhesives

and sealants to products that could be used by collision repair

technicians to repair vehicles. But should they be used? And if

so, on what?

The abundance of advertising done by different

manufacturers would have us believe that with the exception of

structural components – i.e. frame rails, rocker panels and pillars

– we can bond almost anything.

Is this really the case?

Let’s look at some of the thinking around

the industry regarding adhesive bonding – along with recent positions

taken by the OEMs – to help us answer that question.

The OEM Side

The following document was a world-policy

letter issued by the Ford Motor Company in February:

Use of Structural Adhesives for

Body Repair Issue

Ford Motor Company is concerned about

the potential effects of aftermarket structural adhesives advertised

as complete or partial replacement for MIG plug welding on the

safety, durability and quality of Ford vehicles involved in collision

repairs. Based upon the information currently available on these

materials, Ford Motor Company does not endorse or recommend the

use of these adhesives in place of MIG plug welds for collision

repair.

Differences Between Welding Bonding

and Adhesive Bonding

There are clear differences between

weld bonding and adhesive bonding that need to be considered in

discussions of vehicle manufacturing and repair with adhesives.

The American Welding Society defines weld bonding as a resistance

spot welding process variation in which the spot weld strength

is augmented by adhesive at the faying surfaces. Adhesive bonding

is a method for joining similar or dissimilar materials relying

on the adhesion properties between the adhesive and adherend.

Ford Motor Company at present only

utilizes weld bonding in the manufacture of steel body structures,

not adhesive bonding.

Rationale for Concerns

1. Vehicle performance:

a. Current advertising of aftermarket

structural adhesives appears to stress safety and crash performance.

Suppliers indicate they have conducted crash tests of manufacturers’

vehicles, compared the performance of vehicles repaired with structural

adhesives vs. vehicles repaired with MIG plug welding and concluded

that the crash performance is essentially the same. Aftermarket

suppliers imply that because their selected vehicle crash tests

were apparently successful, their repair materials and procedures

are suitable for other spot-welded sheet-metal parts on all other

makes and models (except "structural" parts), under

all collision scenarios, all environmental and operating conditions,

and all possible ages of vehicle, and will completely restore

the structural integrity of the vehicle. Ford Motor Company cannot

accept this logic.

b. Ford Motor Company currently uses

structural adhesives with spot welding to improve Noise/Vibration/Harshness

(NVH) and durability, not for safety. It cannot be implied from

aftermarket advertising that the use of adhesives in place of

MIG plug welds will restore all of these characteristics.

c. Aftermarket adhesive suppliers appear

to focus on the lap shear as the primary characterization of adhesive

strength. Other important factors that are not clearly advertised

are modulus, peel strength, toughness and crack propagation, under

both static and dynamic load conditions. Because it is not known

how these aftermarket adhesives perform to these criteria under

all operating conditions compared to production spot welds and

repairs using MIG plug welding, Ford cannot confirm the effectiveness

of these adhesives in meeting crashworthiness, NVH, sealing and

durability requirements for the application recommended.

d. Aftermarket testing to date has

not apparently addressed the potential of adhesive bonds developing

nonvisible cracks during minor collisions. This could result in

significant bond failures through crack propagation or peeling

in subsequent collisions.

2. Environmental conditions: Ford Motor

is concerned about the strength of correlation between accelerated

laboratory coupon testing and vehicle field data. Aftermarket

evaluations under the complete range of possible environmental

conditions (temperature, humidity, road salt, time, etc.) appear

to be limited to laboratory testing of plaques, at best, and have

not addressed accelerated durability or temperature extremes.

3. Robustness of materials and processes

relating to variations in shop conditions: Ford has not seen evidence

that the quality of repairs with these materials is robust enough

to all the potential variations in technician skill level, environmental

conditions, types of repairs, etc., that will be encountered in

the field. For example, adhesive performance is dependent on a

consistent adhesive bondline thickness. Since mating panels on

damaged vehicles will likely require straightening before a replacement

panel is bonded on, and given the springback characteristics of

high strength steels, we do not believe that body shops have consistent

capability of reproducing production weld-bonded joint gaps with

adhesives alone.

4. Effectiveness of adhesive repairs:

It is not clear how quality control of aftermarket structural

adhesives can be maintained in a body shop environment. Nondestructive

test methods are available, but these methods only detect the

presence or absence of adhesive in the joint, not the quality

of the adhesive cure or adhesion to the substrate.

5. Vehicle design: Ford Motor Company’s

welded steel body joints (width, gaps, etc.) have been optimized

for spot welding, not for all-adhesive bonding. Ford Motor cannot

verify that the use of adhesives alone in these joints without

welding will reproduce the strength, stiffness, dimension, etc.,

of the original production vehicle.

Conclusions/Recommendations

1. Based on the evidence presented

to date, Ford Motor Company does not endorse or recommend the

use of structural adhesives in place of production spot welds

for body panels on its vehicles.

2. The only exception that Ford Motor

supports is the replacement of door outer panels with structural

adhesives and hem flanging, which is an accepted industry practice.

3. Ford Motor Company cannot conclude

from the data provided that the crash performance, NVH, durability

and reliability, over time, of all-adhesive joints will be comparable

to production designs with spot welds or repaired vehicles with

MIG plug welding.

4. Ford Motor Company requests that aftermarket

adhesive suppliers cease advertising their products so as to imply

they are suitable for use on Ford vehicles worldwide.

Advanced Vehicle Technology

Ford Customer Service Division

Ford Motor Company

February 25, 1998

A Ford spokesperson cited that the strong position has been taken

because there aren’t sufficient tests yet to determine the long-term

suitability of the adhesive repair method. At this time, Ford

only approves the use of adhesives on door skins.

Chrysler says it won’t recommend this repair technique at this

time either and that an earlier report widely circulated regarding

the Chrysler Sebring convertible using extensive bonding was in

error.

A spokesperson for General Motors indicated that the company is

working on a position statement and that we should see something

by the end of the summer. The basic guideline, says the spokesperson,

is to replace welds with welds.

The Adhesive Manufacturers’ Side

What follows are responses from adhesive manufacturers to Ford’s

world-policy letter regarding structural adhesives.

- Richard L. Jacobs, president, Polymer Engineering Corporation

– "Ford Motor Company does not endorse or recommend the use

of adhesive in place of MIG plug welds for collision repair.

But have the OEMs forgotten that they have reduced the gauge of

steel panels during the last few years to the point that they’re

essentially paper thin? It seems that nowhere in their planning

were they thinking of how repairmen would have to deal with the

problem of reattaching these panels. What we’re left with now

is to determine how any fixturing method used in the body shop,

including spot welding or MIG plug welding, can provide strength,

absorb energy and provide quality, durability and safety to the

motorist.

It doesn’t matter how large the welds are or how much I-CAR has

perfected welding methods. The failure point upon impact becomes

the thin steel panel at the weld perimeter. And more than that,

the welding standards adopted by both OEMs and I-CAR only require

that the weld be of a certain size and quality. Nowhere in the

published standards do they provide any idea of how little force

is required to delaminate a welded panel by failure of the panel,

not the weld. They address the construction of the weld but not

the weakness of the weld edge. So, we at PEC have gone about testing

welds of various constructions and configurations to determine

their strengths, and we’ve found that our adhesives (and even

those of most of our competitors) are substantially stronger than

either a spot-weld attachment or a MIG plug-weld attachment to

the panel. Adhesive bonding provides substantially more strength,

quality and durability, mainly because adhesives can cover so

much more of the overlap contact area of the panel to the frame.

I-CAR has made a concerted effort to establish MIG plug-welding

methods that produce a fused overlap of panel sheet metal to frame

steel. However, the process requiring the 3/8-inch diameter fused

overlap between the frame and the panel is extremely difficult

to achieve. Not only is this process labor intensive, it’s not

learned quickly; proficient welding skills require perhaps years

to achieve. You must also add to this the labor time required

to dress down each weld. Welding also leaves several secondary

repair problems, such as the potential for corrosion and dimpling

and does nothing to solve the problems of NVH. …

Some OEM structures such as floor pans have been weld/bonded to

overcome NVH. Body shop repairmen have been faced with a dilemma

in repairing these structures. Should the refixturing be accomplished

by welding first and bonding second or vice-versa? If they weld

first and bond or seal second, as has been suggested by some OEM

engineers, a fertile ground becomes available for corrosion in

these structures, where the oxidized and corrosive remnants of

welding are left within the sealed pocket to instigate corrosion.

If repairmen bond first and weld second, a combustibility issue

arises. Also, the question arises as to why one should weld if

the adhesive is substantially stronger than the weld/bond anyway?

PEC specifically avoids making any recommendations where these

constructions are structural. In the case of structural weld/bonded

applications, OEMs have left body shops without an answer. …

Of course, it’s a legitimate question as to how vendors have verified

safety, quality and durability. Adhesive bonding provides a good

alternative to welding. But we should not glibly think that bonding

is the panacea. There’s much more to bonding than meets the eye.

Not only must the reliability be proven by considerable testing,

there are many hidden and different engineering considerations

that pertain to adhesives over welding. While welding has several

disadvantages, welding can be relied upon to provide stable fixturing

properties over the range of service temperatures. And the problems

of welding are known, while the effects of adhesive bonding are

relatively unknown. However, it’s a disservice to suggest that

the vendors have not done their testing to verify safety, quality

and durability. We, as one vendor, have done substantial testing,

and accelerated testing is a reliable means of establishing durability.

We have used welding as the basis by which the various adhesives

are compared to automotive applications and have performed the

following tests using frame steel and panel steel:

- Compared adhesive bonding to spot welding and MIG plug welding

per I-CAR and OEM specifications over a full range of service

temperatures. - Tested modes of force, including tensile, compression, lap

shear, peel, flexure and torsion. - Done accelerated and long-term aging.

- Related bonding to intrinsic properties of steel using both

theoretical and practical approaches. - Performed stress/strain relationships and modulus of elasticity.

- Tested tensile and elongation over a range of service-temperature

conditions. - Tested various overlap joint constructions under load-bearing

conditions. - Tested energy absorption over a full range of service temperatures.

- Taken into account worst-case conditions of maximum open times,

minimum cure schedule, maximum heat exposure and at service-temperature

extremes. - Tested performance under real driving conditions.

- Performed crash testing with successful results.

These studies were intended to satisfy PEC management that adhesive

materials have been tested at the maximum of extremes using the

best engineering considerations and methods.

The use of adhesive bonding in the autobody aftermarket will continue

to grow, and along with that will be the growing need to establish

universal specifications and rigid testing standards. The leaders

in the autobody aftermarket (I-CAR, insurance companies, manufacturers,

etc.) must spearhead the establishment of such industry standards

because the OEMs will be slow to react and will always be the

last to endorse new techniques for fear of liability."

Joseph L. Luchik, director of marketing, Lord Corporation –

"Lord Corporation has as its mission in the automotive repair

industry to offer innovative, cost effective ways of repairing

vehicles and restoring them to original factory condition. Lord

is a leader in the design and development of adhesives for bonding

a number of difficult-to-bond substrates used in a variety of

industries, including automotive OEM and repair. During the past

few years, Lord has conducted independent vehicle crash tests,

which supported the concept of metal bonding replacing MIG welds

in nonstructural applications. Data generated from these tests

has been made readily available. Lord will continue to work closely

with the industry to further define the testing needed to validate

this cost effective form of repair."

- Steve Fussy, director of marketing, SEM Products, Inc. – "SEM

markets products that address the needs of autobody technicians,

and we place tremendous faith in their abilities. Our products

are developed to solve problems body men and painters face every

day and to perform effectively in the environment in which these

professionals operate.

Obviously, there are applications where metal autobody components

can be bonded safely creating a repair offering integrity for

the life of the vehicle. However, it is neither SEM’s policy nor

intent to recommend procedures that contradict directives of automobile

manufacturers."

- Jon Fryxell, marketing manager, 3M Automotive Aftermarket

Division – "3M is a worldwide leader in adhesive technology.

Over the past eight years, 3M has developed specific adhesives

for use in panel bonding applications. 3M’s adhesive process virtually

eliminates heat metal warpage and risk of fire, glass and trim

damage, while enhancing the technician’s safety environment.

– 3M’s adhesive bonds along the entire length of a panel rather

than just the specific MIG-weld points.

– 3M’s adhesive has a built-in corrosion inhibitor.

– 3M’s glass bead technology assures uniform adhesive thickness.

– 3M’s field representatives, training materials and videos for

the technician greatly reduce the variability in repair of the

vehicle. Variability can be a significant problem with welding,

as the spacing and quality of each weld are determined by the

individual technician. As a result, fixes may range from very

good to very poor. 3M’s adhesive, on the other hand, bonds along

the entire line of the application and develops a shear strength

along that entire line.

OEMs clearly know how to make cars best in a controlled and fixed

environment. They have the robotics, computers and engineers to

make a fine product. However, in the aftermarket, when we try

to fix these modern miracles, we often need to employ different

technologies. 3M is committed to working with all segments of

the collision repair industry to continue to improve repair procedures

and technician safety."

The Insurance Side

The insurance company people I spoke with rely on information

commonly available to the industry to set guidelines for authorized

and approved repair methodology. It’s common for them to look

at the information available from I-CAR, Tech-Cor and vehicle

manufacturers, and if there’s a controversy regarding a repair

process, they default to vehicle manufacturer guidelines. (With

that in mind, some of the following insurance people may well

change their policy regarding adhesives once the positions taken

by the OEMs become common knowledge.)

Most insurance people I spoke with believe there’s a place for

adhesive bonding. They’re aware that some form of crash testing

has been done by many adhesive vendors and that corrosion protection

with bonding might be better than it is with a weld that disrupts

the anticorrosion properties of a new panel. They’re also aware

that there might not be a time savings using adhesives because

of the upfront flange straightening, panel prepping and dry fitting

required to achieve a well-fit panel replacement. They advised

testing the waters in your own market because every company has

its own spin on compensating shops for these materials.

As mentioned, most of the insurers I spoke with believe there’s

a place for adhesive bonding in collision repair. Most, but not

all. When I asked State Farm about its position on bonding vs.

welding, I was told by Brian Maze, State Farm’s public affairs

specialist, that "To State Farm’s knowledge, none of the

auto manufacturers have approved substitution of bonding material

for welding. Therefore, we will not consider bonding to be an

acceptable repair – except in the cases where the panels were

bonded by the manufacturer."

Is it only a matter of time before other insurers follow State

Farm’s lead?

The Shop Side

There seems to be a dividing line at the shop level: Shops either

utilize metal bonding adhesives or they don’t.

In shops that use this technology, the shop managers I spoke with

typically let their technicians decide whether to weld or bond

a replacement panel; they said they’ve invested in training for

their techs and feel they’re capable of making the right choice.

They also said they have fewer wind and water leaks, and sparks

flying into vehicle interiors have ceased to be a problem.

The other school of thought is not to utilize adhesives for collision

repair. These shop owners have invested in equipment, training

and certification for their technicians as welders and will only

use adhesives on vehicles that were originally assembled with

adhesives.

Note: Some vehicle-recall campaigns involve delamination or loosening

of outer skins from their panel frames, and factory-recall bulletins

specifically outlining a field repair method involving the use

of a panel adhesive are available. These are isolated instances,

and shops involved in these campaigns should simply follow the

manufacturer instructions to perform a repair.

I-CAR/Tech-Cor Sides

Regarding the use of adhesives for collision repairs, a spokesperson

at Tech-Cor says: "Officials at Tech-Cor said that bulletin

96-3 is their most current comment on this matter. It is neither

a recommendation nor a condemnation of adhesive bonding of nonstructural

panels. It merely outlines the steps to be taken if the choice

is made by the repairer to use this method."

Where does I-CAR stand? The I-CAR Advantage publication, Vol.

IX, No. 6, dated November/December 1996, had an article about

repair adhesives, and the following are excerpts from that issue:

Potential liability: "The liability of using a product incorrectly

will lie solely with the repair facility. So, if you decide to

use an adhesive where it is not recommended, you will lose the

support of both the OEM and the adhesive maker. All adhesive products

have a disclaimer that generally states if the product is used

improperly, the adhesive maker assumes no liability."

The future of adhesives: "It’s important to keep in mind

that OEM repair recommendations will dictate when, and if, adhesives

will become an acceptable method of repair."

Conclusions: "Adhesives are stronger and more durable today

than ever before. For this reason, it is very easy to start thinking

that using a repair adhesive to attach a panel is equal or better

than MIG welding. To use or not to use adhesives is a decision

based on many variables, but most importantly, does the vehicle

manufacturer recommend it?"

Which Side to Take

If you aren’t seriously confused by now, you probably didn’t read

the whole article!

The issue of bonding vs. welding has reached critical mass. Part

of the problem is that the OEMs build vehicles but don’t repair

them, while we, in the industry, don’t build vehicles but must

repair them.

Is there middle ground?

If there is, it has yet to be found. Until that time comes, shop

owners and technicians will have to base their decisions of whether

or not to use repair adhesives on current facts and information.

Unfortunately for adhesive manufacturers, the facts at hand don’t

appear to be in their favor.

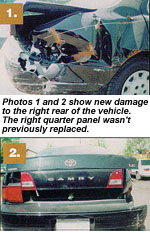

The pictures of the Toyota Camry point to a lack of communication

to the repair segment of the industry, which then points to a

liability issue for the repairer that simply cannot be ignored.

And with the current OEM position, which is typically followed

by an insurance-industry position, it would appear that a shop

owner who chooses the adhesive path does so at his own risk.

Writer Michael Regan is president of The J.J.R.

Company in Cleveland, Ohio, and a contributing editor to BodyShop

Business.

Pictured is a 1995 Toyota Camry that was involved in a collision

60 days ago. The left quarter panel, deck lid, bumper and rear

body panels were replaced, and the trunk floor panel was repaired.

The quarter panel was replaced utilizing a belt-line cut that

allowed the rear glass to be left in place, and it was MIG welded

at the front edge in the door jamb, welded around the wheelhouse

and – with the exception of a 1 1/2-inch tab at the front edge

of the trunk jamb – welded in the jamb. It was also attached to

the rear body panel using welds. In the sail-panel area, the choice

was made by the technician to fit the panel with a 1 1/2- to 2-inch

overlap and to use a metal-bonding product to attach the panels

together. This was done, and the panel was finished in the normal

manner and painted.

Earlier this week, the vehicle sustained a hit to the right quarter-panel

area. As you can see in the photos, it was a good hit, causing

quite a bit of damage to the right rear of the vehicle.

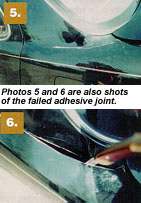

The surprise comes from a re-examination of the left quarter-panel

belt line. The bonded joint failed, and there appears to be adhesive

residue on both sides of the open tear. But close examination

of the original MIG welds at the front door-jamb edge, the rear

body-panel and trunk-floor areas and the upper quarter attachment

behind the start of the glue joint show no failure at all. What

happened?

The car was repaired at an I-CAR Gold Class shop, and the technicians

have decades of experience, are I-CAR certified in welding, regularly

attend clinics and training, and are involved in the industry.

They approached the original repair just like the ads told them

to: "Save time, leave the glass in place, don’t worry about

a thing." The product they used was a choice of several from

a certain manufacturer. The manufacturer’s technical answer man

now says the shop probably should have used one of the other products

in the line – that one of the others may have been a more suitable

choice for this repair.

Seeing this vehicle, I suddenly realized what the Ford spokesman

was saying: There needs to be a gigantic meeting of the minds

between adhesive manufacturers and vehicle manufacturers to coordinate

testing and training that will minimize cases like this Toyota.

Somehow, years ago, the paint manufacturers got together with

vehicle manufacturers and came up with a complete set of repair

procedures that we follow in the field. Paint companies relied

on their OEM experience to initiate approval for refinishing of

vehicles. Since many of the adhesive manufacturers say they have

a strong OEM presence, maybe they need to go to their OEM connections

to find out what it will take to work together to come up with

joint (no pun intended) recommendations for panel replacement

for collision repairs. To date, the recommendations for using

adhesives for nonstructural panel replacement have been one sided

– yet repair professionals and vehicle owners would both benefit

from repair procedures that are endorsed by the adhesive manufacturer

and the vehicle manufacturer.

Note: None of the MIG welded areas of the original repair show

any evidence of failure. The failure on this vehicle is confined

to the belt-line area where the choice was made to use adhesive.