When it comes to body shop layout and design,

most shop owners would kill – or at least maim – to get their

hands on that one, perfect setup.

It’s probably a good thing, then, that there

isn’t one.

Though some shop owners think there’s "one

perfect plan," what works best for you may not work so well

for Billy Bob down the street. Good, workable layouts depend on

your location, facility, the type of work you do, etc. Definitely

no cookie cutters here.

Though no "best" shop layout is

the same, there are some general rules to follow (see "Blueprint

Boo-boos" on page 46), and learning from what others have

done is the best way to start your layout-and-design wheels turning.

See what you can come up with for your shop after being let in

on how three owners remodeled to optimize their operations.

Schmidt’s Auto Body, Fresno, Calif.

In 1992, owner Dennis Schmidt constructed

an additional, 5,000-square-foot building (a twin to the original)

about 50 feet from his existing building – in which the shop had

done business since 1964.

In 1996, Schmidt decided to redesign. Before

getting started, he retained some professional help, based on

a recommendation by his paint manufacturer. Besides recommending

this outside help, his manufacturer also offered two suggestions:

Schmidt needed to move the noise of the body shop away from the

front office and to create more working area due to increasing

business volume.

Following the redesigning and remodeling advice,

Schmidt’s gained improved office efficiency and a more professional,

comfortable office area – which is important for an I-CAR Gold

Class shop to have.

The office, located in the original facility,

is now more up to date. According to Schmidt, the office had three

desks (ones built in the ’40s) and was very outdated. Now, instead

of desks, the office area has modern workstations, an updated

phone system and an additional office. Previously, open space

and two restrooms occupied the area behind the original office,

so by extending the office area farther back, the new office gained

a restroom – a big plus for customers and insurance adjusters.

Another plus for adjusters are the workstations.

The office area still isn’t very large, but

the redesign gave employees much more space in a very limited

area (it’s large enough now to accommodate a complete staff).

According to Schmidt, the biggest benefit of the redesign of the

office area is that it created a much cleaner and more comfortable

space in which to work. Customers have commented on the change:

"They feel like they’re walking into a more professional

office than just what the typical body shop of yesterday looked

like," Schmidt says.

Because of the redesign, customers have at

least three things they didn’t have before: a waiting room, a

unisex office restroom, and some peace and quiet.

The peace and quiet was obtained by moving

the body shop from the front half of the production area, which

is near the front office, to the rear of the production area.

Now, detail work, pinstriping, headlight aligning, light reassembly

work and A/C recharging are done near the office – also good in

that it keeps the finished product close to Schmidt. "If

I see any defects or problems," he says, "I can send

it back to the body shop or paint shop for corrections."

Moving the body shop – to where the paint

shop used to be – also allowed more working area for the metal

and frame departments because it went from 2,000 square feet to

3,000 square feet; the paint shop was then moved into the new

building. Moving the frame and body shop to the far end of the

building made it possible to have three stalls, each with a frame

rack beside it. Now, each technician and his helper can work on

one car; and after the frame is straightened, they’re able to

bring the car down and put another one up. The additional space

made it possible for Schmidt to acquire a third, much-needed frame

rack.

The paint department also grew from 3,000

square feet to 5,000 (not counting the outside overhang, which

gives the building an extra 2,000 square feet on each side and

is used to prep vehicles or put on moldings, etc.)

Besides purchasing a new frame rack, Schmidt

installed a new downdraft spraybooth, a four-wheel alignment rack,

and an A/C R12 and R134a recharging system. Schmidt’s original

paint booth is still located near the center of the original production

area and is used primarily for jamming parts.

A year and a half and about $175,000 after

the project began, Schmidt says his employees now have the room

they need to be more efficient, and work flow has greatly increased.

"We feel our decision to have a facelift has been a very

worthwhile venture," he says. "Profits are up, along

with productivity. Our employees are happier and take pride in

their repair work with the new space and equipment."

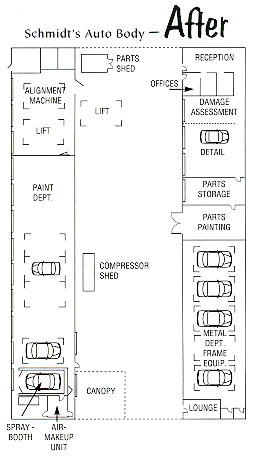

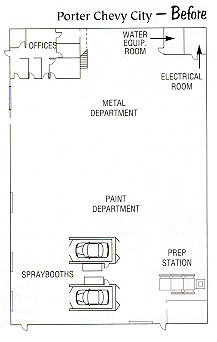

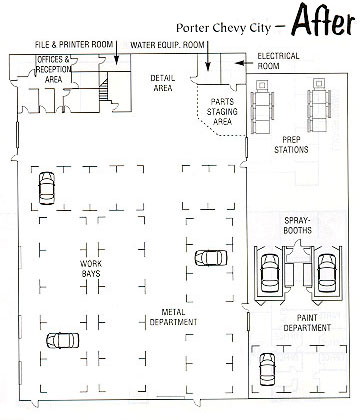

Porter Chevy City, Newark, Del.

Due to the sheer volume of work it’s been

receiving, this body shop is currently expanding to expedite the

flow of work through production, therefore ensuring customer satisfaction.

Body shop manager Charlie Smith says an overabundance

of work due to multiple direct-repair and select-repair programs,

as well as a reputation for quality repairs, left him with no

choice but to expand; he has to in order to satisfy the shop’s

clients. To accomplish this, Smith chose a professional design

based on the advice of his paint manufacturer.

The expansion, which dealer owner Cory Porter

has been very supportive of, is coming along very quickly: The

structure is already built and connected to the present shop,

and it’s expected to be completed mid-month.

"We expect exciting by-products from

this expansion," says Smith, "such as the ability to

perform "express repairs" and, as a direct result of

that, a decrease in car-rental costs to both vehicle owners and

insurance companies. Smith explains that a four-day repair usually

runs over into five or six days. With the new facility, Smith

hopes to reach the goal of meeting repair times allowed by insurance

company estimates. He also hopes to make more money by being able

to repair more cars.

The expansion has doubled the shop’s size

– from 15,000 square feet to 30,000 square feet. And by adding

a two-story addition to the shop, Smith was not only able to completely

separate the body and paint departments, but also to separate

paint from paint prep. "We anticipate a dramatic decrease

in the need for buffing and wet sanding," he says. "This

dust-free paint environment will be the first of its kind in our

area."

Smith estimates the shop’s final outpay for

the project to be $600,000, but he also anticipates this investment

to pay for itself within five years. The expansion hasn’t yet

affected production, but Smith plans on measuring the increase

in productivity on a weekly and monthly basis by tracking productive

hours of technicians, parts sales, hours per RO (how long it takes

techs to repair a car), etc. Though he expects an increase in

production, Smith doesn’t anticipate seeing it until the addition

becomes fully operable.

He also anticipates some production challenges

when the time comes to relocate the paint booths. "The important

thing is to plan for production challenges," says Smith.

"Have meetings with your staff prior to any anticipated problems

or delays. Let your office and shop staff be aware of probable

side effects the expansion may have both during and after completion."

One side effect for Porter Chevy will occur

when Smith extends the hours of operation as it becomes necessary,

which will include Saturday hours and two shifts. He also plans

to expand and redesign the shop’s office, taking it from 1,200

square feet to 2,400 square feet. "When planning an expansion

or redesign, don’t forget about your administrative facility and

personnel," says Smith. "A smooth, easy-flow design

and staff in your office will be echoed by a free-flowing production

staff. Your office also needs to be able to accommodate not only

additional staff members necessary to support your increased volume,

but also higher traffic of adjusters, reinspectors and customers

waiting for estimates."

Smith also offers this advice to any shop

owner considering expansion and/or redesign:

- Fools rush in. Make sure you have consistent volume

over a two- to three-year period. - Max out your existing facility before considering alterations.

- Get help. Don’t try to design your facility on your own; call

professional layout and design planning companies to do a facility

evaluation and a market-share survey before you commit to alterations.

Auto Body, E.R., Akron, Ohio

An investment banker, Auto Body, E.R. President Mathew Hanson

found himself wanting to enter the collision repair industry and,

in doing so, wound up having to transform a former track and racquetball

club into a body shop.

Hanson first encountered the collision repair industry while assisting

FinishMaster, Inc. – a paint, body and equipment supplier (PBE)

– in making 33 acquisitions of smaller PBE operators. As a result

of this experience, Hanson got the urge to enter the industry

and then spent 18 months researching it – with the intention of

making acquisitions of existing collision repair businesses. While

unsuccessful in buying a facility, he remained committed to becoming

an industry player and decided to enter the industry on a start-up

basis. After researching the market for several months, Hanson

located the racquetball-club facility, which was in an area that

had a need for an independent repair facility.

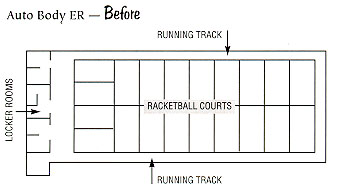

Hanson’s entire building is about 29,000 square feet, including

a mezzanine area. The entrance had a front-counter area, a couple

of offices and a small laundry room. In addition to the men’s

and women’s locker rooms (complete with whirlpools and saunas

– which no longer exist), the club had a running track, 12 racquetball

courts, and area with exercise machines and an aerobics dance

area.

Auto Body, E.R. leased about 12,000 square feet of the metal-clad

building, and the remodeling and planning began in mid-January

1997. Since Hanson was anxious to open his doors as soon as possible,

he really pushed to have the layout completed quickly; to do this,

he summoned professional help. Hanson retained a layout and design

planning company to prepare the shop layout, and with the dimensions

of the building as the only constraint, Hanson asked that the

design maximize production potential.

"I have to admit," says Hanson, "I was a real pain

in the design process. [The design company] produced the first

layout design, and I couldn’t believe that the plan they had created

was the right way to configure the building."

As a result, Hanson had them reconfigure the design three or four

different ways. "I’m a little embarrassed to admit that I

ultimately chose their original plan," he says. "In

retrospect, I should have realized that, as experts in layout

design, they would have considered all of the options before they

submitted the first plan. When you utilize experts, you need to

take advantage of their expertise."

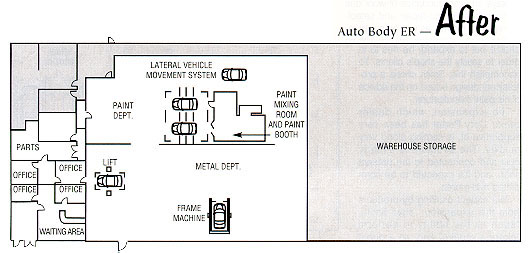

The final design has worked very well for Auto Body, E.R. The

original reception area and offices were remodeled into a customer

waiting area with a customer restroom, a counter/workstation for

a customer-service representative and an office for the shop manager,

with an extra office for insurance adjusters to use; the office

area has a total of 955 square feet. The locker rooms were then

converted to a parts room (265 square feet), an employee lunch

room and an employee restroom.

As customers are waiting for an estimate or delivery, they can

view the shop from the reception area through a large window.

The customer-service representative is strategically positioned

behind the front counter, and the manager has a separate office

for preparing and selling estimates.

In the production area, all remnants of the fitness club were

removed, including interior walls and racquetball courts – with

the exception of a center wall, which was left to divide the metal

and paint production areas. In addition, drainage was added to

accommodate a detail area, and firewalls had to be erected, which

left a remaining 10,000 square feet of production area (metal

getting 5,200 square feet and paint 4,800 – due to a hallway leading

to an emergency exit).

The layout plan of the facility anticipated the flow of production

and effectively provides 22 bays, 11 in the metal department and

11 in the paint department. Upon entering the shop, you’re in

the metal department. Vehicles move from the metal shop to the

paint shop through a garage door in the center wall and then back

to the metal shop for reassembly through another garage door.

The design correctly allows a wide lane for reassembling and moving

vehicles. In addition, the paint area strategically positions

the downdraft spraybooth with the air make-up unit on the roof

and utilizes the slightly irregular (wider) shape of the prep

area. "While we’re not at production capacity yet, it’s obvious

that the layout will maximize the capacity of this facility,"

says Hanson.

For Hanson – who splits his time 50/50 between the body shop and

his investment banking business – the single biggest frustration

was dealing with the independent contractors who were operating

on their time schedules, not Hanson’s: He wanted an April 1 opening;

he got a May 1 one.

When he remodels again, Hanson says he’ll prepare a time schedule

for activities and then have a production meeting with all the

contractors. After they agree to the schedule, he says he’ll implement

a monetary penalty, per day, for missing production deadlines.

"I believe that the potential loss of money is the most effective

way to focus a contractor’s attention," he says.

Learn Through Examples

Though all these layout and design ideas may not work for your

shop, they illustrate options and how different shop owners tackle

the same kinds of problems.

Because there’s no "one perfect layout" that’s going

to fix every shop’s production problems, take what applies to

you and leave what doesn’t. These shop owners solutions may not

solve your problems, but they may give you an idea about what

will.

Writer Eileen Benedict is associate editor of BodyShop Business.