If you’re like most collision repair business

owners who’ve been around a while, you probably consider your

pride and joy a "single line" business. Except for a

few minor scratches and paint jobs, not too many customers wake

up in the morning and decide they want collision work done on

their vehicles. It is, instead, strictly by accident (excuse the

pun) that they end up in your shop. Hence, when weather doesn’t

cooperate and accidents are down, collision repair work decreases.

So, now that the El Nino has turned the nation’s

weather pattern upside down for at least this year and insurance

claims have dropped more than 30 percent in some areas, what are

your plans to survive? Because much of our industry relies on

the misfortune of others brought on by adverse weather conditions,

when the weather doesn’t cooperate, many areas have too many collision

facilities and not enough available repairs.

You could hope for a May snow storm, some

real big hail storms or even another hurricane (probably not likely

in the Midwest), but why build your future on chance?

Today’s opportunities are endless.

A progressive operator needs to think "auto

care," not just collision repair. In addition, consider the

income that could be realized doing some or all operations that

are currently sublet, such as mechanical repairs.

Considering the Job

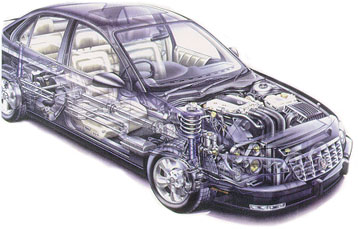

Vehicles today are much different than those

of 20 years ago. Back then, the closest thing to mechanical repairs

after a collision was changing a water pump, clutch fan, motor

mount or alternator. Of course, you could also open the hood and

see ground! Today, electronics and mechanicals are damaged consistently

in most accidents, so if you sublet these out, you may be throwing

away dollars.

In this article, I’ll discuss two main types

of mechanical work: retail work and internal work. Retail work

includes income from mechanical repairs not caused by the accident.

In other words, the customer came because he specifically needed

mechanical work done or was "upsold" on additional services

needed during the collision repair. Internal work includes mechanical

work done in conjunction with the collision work and is a direct

result of the accident.

Internal Mechanical Work

You may currently be subletting many mechanical

operations, and there may be many reasons for this: "No one

on staff is qualified (see box on "Finding the Right Employees),"

"I don’t have the needed ‘high tech’ equipment," "No

space or time," "The mechanical shop is right next door,"

"No desire to diversify," "The mechanic is my best

buddy and I went to high school with him," "They are

very good," "I don’t need much mechanical work done

due to the type or size of my business" or "I already

make a 40 percent gross profit on all sublet repairs."

Do any of these sound familiar? In most cases,

one or more of these is the reason most collision shops don’t

do mechanical work, but the last two are the only ones that need

further analyzing; the others aren’t good enough.

If your volume is very small or your work

mix doesn’t justify it, it probably is too costly to do internal

mechanical work. Let’s hope, then, that you’re currently getting

at least 40 percent gross profit on all your sublets!

As for facilities doing a sufficient volume

of sublets, the consideration is primarily how much gross profit

is being made (or lost) on how you’re currently doing it. (Before

considering this, look at timing as well. In today’s competitive

marketplace, one key element of comparison is "turn rate."

How fast can the customer get his car back? In most cases, doing

mechanical work internally will allow for a quicker turn rate.)

Gross profit margins on internal jobs should

exceed 40 percent. But, if you can get 40 percent gross profit

without doing it yourself, just looking at direct profit on internal

jobs may not be enough to convince you to take on the work. There

is, however, much more to the equation.

Keep in mind, you won’t get rich fixing cars,

but you may get wealthy by utilizing your business to acquire

assets. These appreciating assets will, over time, make you wealthy

or your business very valuable. Even if you can get 40 percent

gross profit on all sublets, obtaining property and a building

and doing all mechanical work there at a slightly higher gross

profit while paying for the assets will be a much more profitable

course of action for the long term.

Retail Mechanical Work

It’s here that retail mechanical work enters

the picture. Let’s do some math. Let’s say you do 1,000 collision

jobs per year. In five years, that’s conservatively about a 4,000-person

customer base (excluding multiple jobs for fleet accounts or individuals

and normal attrition). If you could do $200 of mechanical work

to 20 percent of these jobs per year at a 45 percent gross profit,

how many dollars per year is that?

4,000 X 20 percent = 800 customers;

800 X $200 = $160,000 gross sales;

$160, 000 X 45 percent = $72,000 gross profit.

What type of work, you ask? Just look at the

possibilities of a $20 oil change. That would normally be something

each customer would need done three times a year on average. Using

50 percent as the gross profit margin, that produces $24,000.

And during each oil change, a safety inspection is performed,

A/C system is checked, brakes are examined, emissions are checked

and needed wheel alignments are identified for additional mechanical

services on, let’s say, just 30 percent of the visits. What does

that translate to?

Then there’s the cross over: detailing jobs,

complete body checks and additional collision work … all

from a $20 oil change! And for those of you in areas where heating

is necessary, the recovered oil can be used for heating fuel and

even for the spraybooth baking cycle.

The grocery industry has used "leader

items" for years. Think about it: How often does someone

go in and buy just the loaf of bread or milk and not pick up other

groceries? Not too often. So what’s stopping you from using this

tactic?

For customer retention, why not give away

a free oil change? What have you lost? Ten dollars? With proper

marketing this doesn’t cost you anything, but it does bring in

additional work.

Other Possibilities for Profit

This concept for oil changes is but one of

the many possibilities; many other internal and retail areas of

mechanical work are profitable for collision repair businesses,

and what follows is a partial listing of them. (To list all the

options would cause this magazine to accrue additional freight

charges from the post office!)

- Passive Restraint Systems -Passive restraint systems

are here to stay, so if you’re subletting this work, you’re really

losing dollars. The reasons I’ve run across for not doing this

type of work are incredible, and many times it boils down to lack

of knowledge and plain fright – the fright being a direct result

of lack of knowledge. One amazing, common reason I hear is, "I

don’t want the liability of being responsible, so I always send

out air-bag work." Well, I have some unfortunate news …

you’re still liable! Your customer has a contract with you, not

with whom you elected to do the work.

Look at it this way: If you hired a contractor to build your house,

when you have a problem with something, do you call the carpenter

who did the work or the contractor? You accept the liabilities

whether you do the work yourself, have an employee do it or subcontract

it to another vendor.

As for lack of knowledge, training is readily available for servicing

passive restraint systems, and equipment vendors have clinics

and support, too. Also, the scan tools are very user friendly

and basically walk you through the diagnosis step by step.

- Wheel Alignment – Wheel alignments and wheel alignment

checks are a normal part of collision repair today. I’ve seen

large operations struggle with sending vehicles out each day (up

to four to six daily) and being told that something isn’t correct

or something else needs replaced (remember leader items). In most

cases, large chains have very low-tech people run the alignment

racks because that’s all it takes. Today’s computerized wheel

alignment machines walk a technician through each step of the

operation and, in many cases, show exactly how to perform the

operation in a video segment right on the screen.

Performing a wheel alignment is the easy part; diagnosing what’s

really wrong is the challenge. This is where the collision repair

industry has the advantage. Technicians trained properly on suspension

diagnosis can determine what, where and how much damage is really

there – avoiding the "musical replacement game" that

happens so often otherwise.

Offering this service will lead to more mechanical work, including

brakes, CV joint work, springs, shocks/struts, steering and suspension

components, and even tires and wheel service. Can you be competitive?

Sure, if you look at it like the oil change scenario and distinguish

between an alignment check, maintenance-type alignments that may

only require "setting the toe and letting it go" and

collision alignments that may require a more thorough analysis.

The scope of this article doesn’t allow me to explain in depth

the differences, but procedures and techniques are available to

provide excellent service to your customers at a competitive price.

On the retail side, why wouldn’t your satisfied customers come

back to have their wheel alignment work done by the tech who corrected

their body structure and did their last wheel alignment?

If you plan to stay internal with alignments, there are other

options besides computerized systems that will adapt to your frame

rack setup. These systems are less costly, but they also may not

have the features many computerized systems offer. One common

feature on most computerized systems is the vehicle "print

out." I’ve mentioned in previous articles the power of this

feature for marketing and employee validation, as well as future

documentation. This, by itself, offers great benefits to those

doing wheel alignments on today’s collision-damaged vehicles.

- Air Conditioning Service -Today, with the laws and

certifications involving the handling of refrigerants, many have

just given up and gotten out. But why? The test to become certified

to handle the refrigerant is all but a "cake walk."

Granted, the necessary equipment has changed, but could this really

be your reason for not offering this service?

Since eliminating the production of R-12 and the subsequent use

of R-134a (and other refrigerants) by auto manufacturers, today’s

equipment has to recover refrigerant, clean it (recycle it) and

reinstall it (recharge the system). This sounds complicated, but

it’s very "automatic" with the current equipment. The

systems are extremely user friendly for those who will just follow

the directions. And the systems today can do all the current refrigerants

when properly flushed (if necessary).

As for training, it’s readily available and will include the complete

servicing of A/C systems, including leak and system testing.

This is definitely one area of mechanical work that has major

advantages when done internally and for retail customers. Think

of the oil change scenario again … get your satisfied customers

back again … and again … and again.

- Emission Testing – In some states, emission testing

can be beneficial and profitable for your business. The state

laws vary on much of the regulations and restrictions, but if

your state does have emission testing requirements, it would pay

to look into the possibilities. - Brake Service – Brake service, including anti-lock

brake work, may also be a consideration. These systems, like any

electromechanic system used today, use similar procedures, tools

and equipment, and training that isn’t rocket science is readily

available. For your retail customers, reminders at predetermined

intervals encouraging safety inspections or complete "body

checks" can assist in your capturing the extra $200 per year/per

customer from your customer base.

Other options include exhaust, electrical, head lights and other

driveability areas.

Why Pray for Hail?

Your destiny isn’t totally predetermined by Mother Nature. Just

because she’s not destroying cars and creating chaos doesn’t mean

you can’t turn a profit.

Many business owners would sacrifice their left arm for additional

services to sell their customers. You have the opportunity – and

you don’t need to sacrifice anything.

Much of your business may happen "by accident," but

it’s no accident when shop owners take advantage of mechanical

repairs and market them to their customers to pull in additional

profits.

It’s OK to pray for hail. But, as some shop owners have already

discovered, mechanical repairs may be the answer to those "please

send me more profits" prayers.

Writer Tony Passwater is a long-time industry educator and

consultant who’s been a collision repair facility owner, vocational

educator and I-CAR international instructor; has taught seminars

across the United States, Korea and China; and is currently an

industry consultant. He can be contacted at (317) 290-0611 or

[email protected].